Can Double-Stage Worm Gearbox cope with high torque demand?

What is Double-Stage Worm Gearbox?

Double-Stage Worm Gearbox is a mechanical device that uses two sets of worms and worm gears to cooperate with each other, gradually reducing the speed and increasing the torque output. This design has a higher transmission ratio than a single-stage gearbox, which can achieve more significant reduction in a compact space, and is particularly suitable for industrial equipment that requires large torque and high precision transmission.

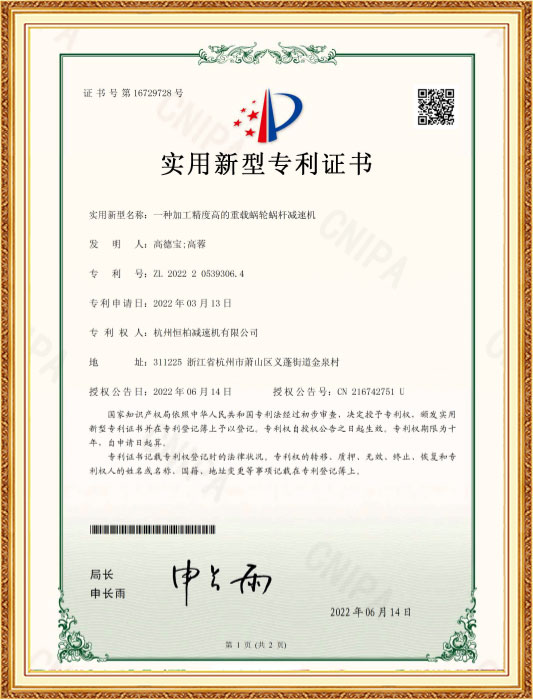

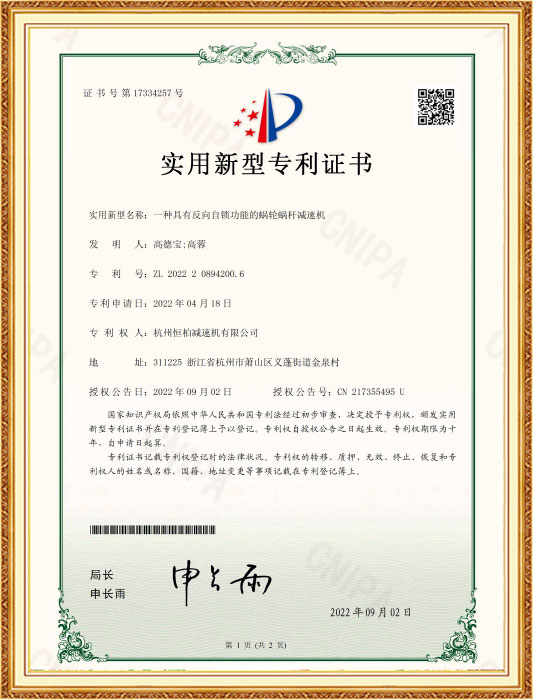

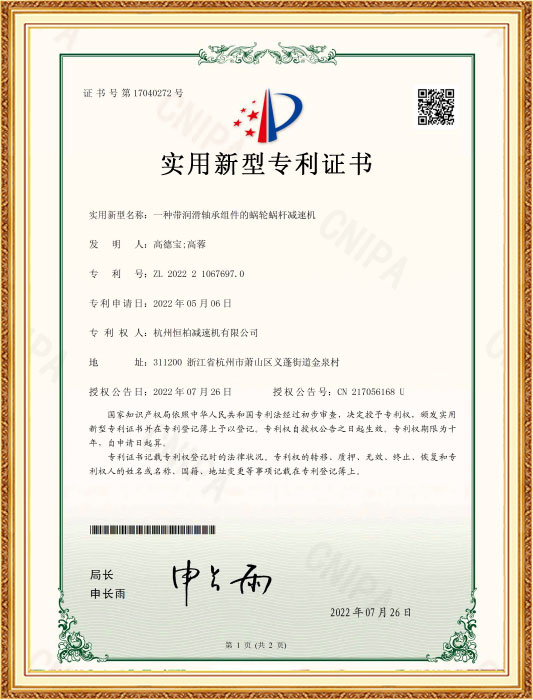

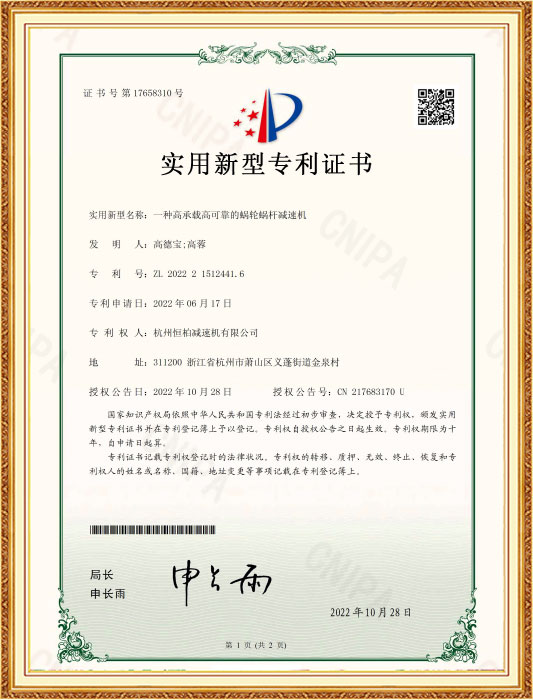

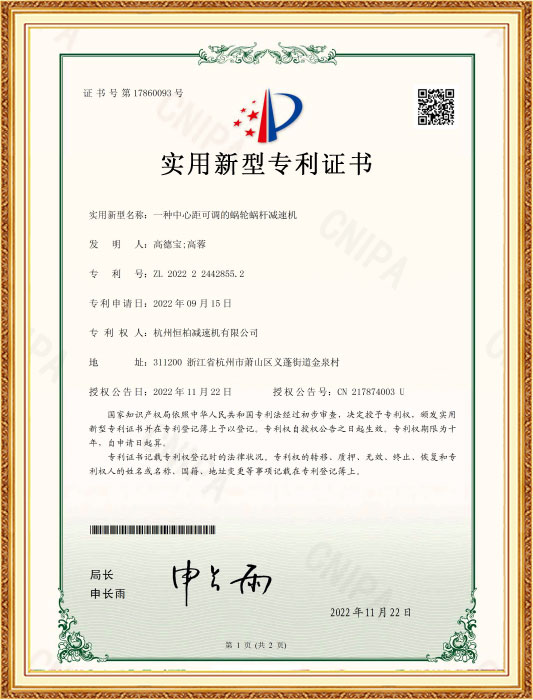

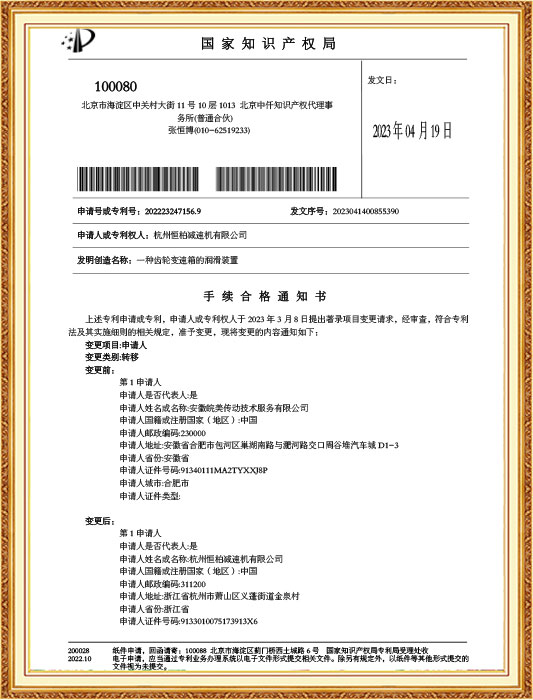

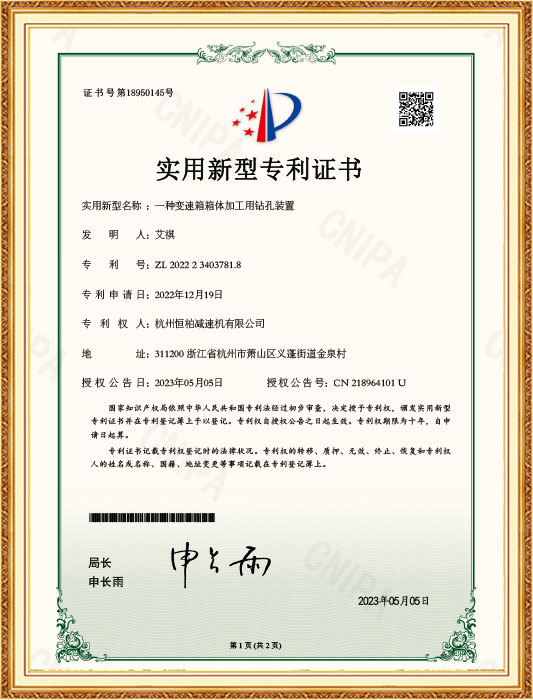

As a leader in the gear transmission industry, Hangzhou Hengbai Reducer Co., Ltd. has developed high-performance dual-stage worm gear reducer products with its deep technical accumulation and advanced production processes. Hengbo's products have been exported to more than 30 industrially developed countries such as the United States, Germany, and France, providing reliable transmission solutions to customers around the world.

Advantages of Double-Stage Worm Gearbox to cope with high torque demand

Double-Stage Worm Gearbox demonstrates outstanding performance in high torque applications. Its two-stage reduction structure can greatly reduce the output speed and significantly increase the output torque, making it an ideal choice for high-load equipment such as cranes, extrusion equipment and large automated production lines.

Advances in modern manufacturing processes have enabled such gearboxes to have excellent load-bearing capacity and optimized thermal management design. Through precision processing and material selection, the product can effectively disperse the heat generated during high load operation, ensuring the equipment's stable operation for a long time and extending its service life.

In addition, the sliding friction transmission method of the dual-stage worm gear reducer allows it to maintain smooth operation under high torque conditions, significantly reducing noise and vibration. This feature makes it particularly suitable for precision equipment with high requirements for operational stability.

Application fields and actual performance

In the field of heavy machinery, Double-Stage Worm Gearbox is widely used in lifting equipment, compression machinery and other occasions where huge loads need to be overcome. Its reliable performance ensures the stable operation of the equipment under high-intensity operation, helping users improve production efficiency.

In the new energy industry, such gearboxes provide precise angle control and power output for wind power generation and solar tracking systems. Through efficient energy transfer, these devices can maximize the use of renewable energy.

It is particularly worth mentioning that the Double-Stage Worm Gearbox produced by Hangzhou Hengbai Reducer Co., Ltd. has performed well in extreme environments. With precision sealing design and high-quality material selection, these products can maintain long-term and reliable operation under harsh working conditions, meeting the needs of various special application scenarios.

With its high transmission ratio, large torque output and stable and reliable performance, the dual-stage worm gear reducer can fully meet all kinds of high torque needs. With the continuous advancement of manufacturing technology, modern dual-stage worm gear reducer products are providing industrial equipment with increasingly efficient and stable power transmission solutions.

English

English 中文简体

中文简体 Español

Español