How does the shaft diameter dimension of K series helical gear motor affect device adaptation?

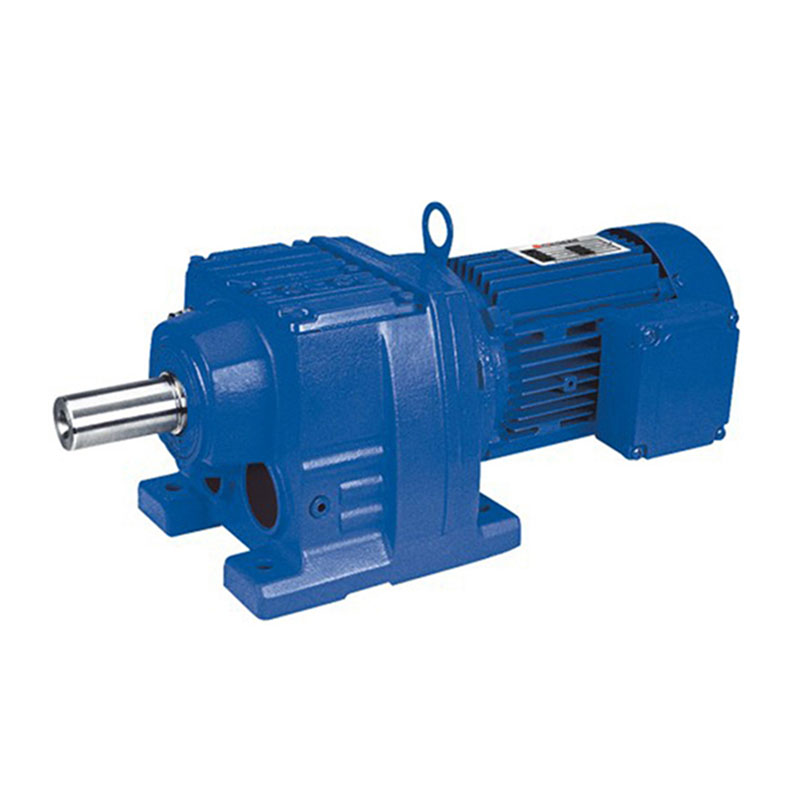

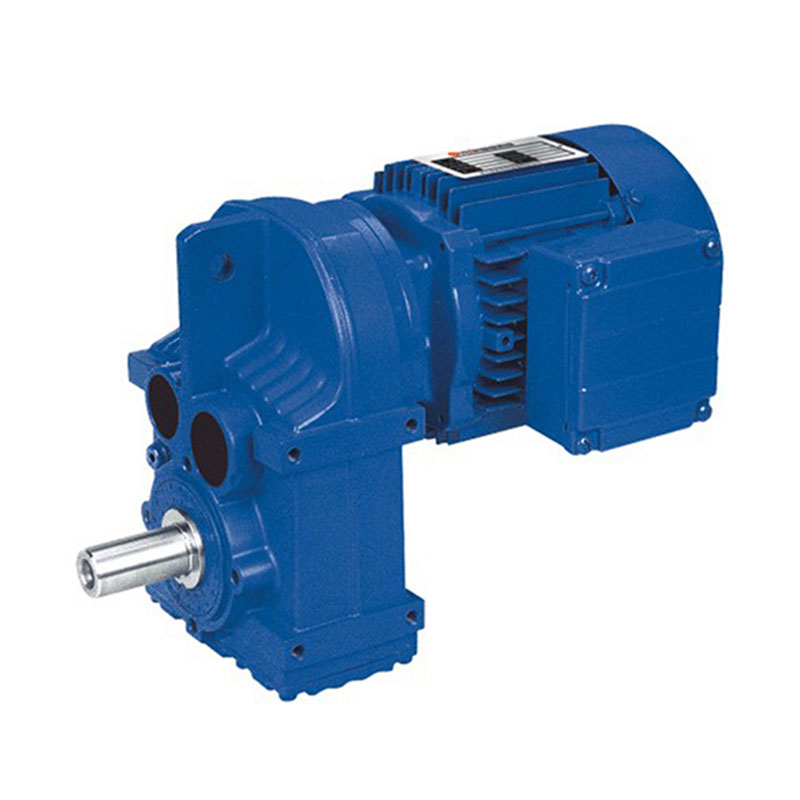

In the field of industrial transmission, K series helical gear motor (K series helical gear motor) is widely used in packaging machinery, conveying equipment, textile machinery and other scenarios with its efficient and stable power transmission performance. However, the choice of motor shaft diameter is a key factor in determining whether it can be perfectly adapted to the equipment, and it is closely related to it from power transmission to equipment life.

1. Shaft diameter and power transmission efficiency

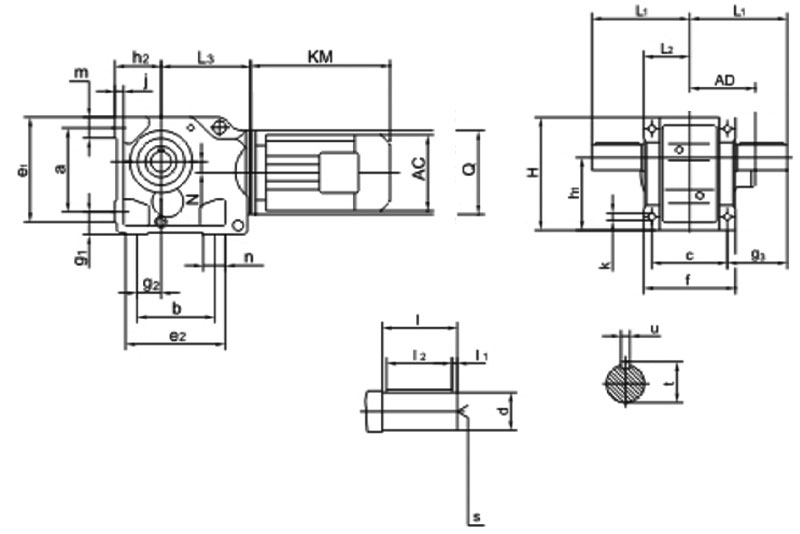

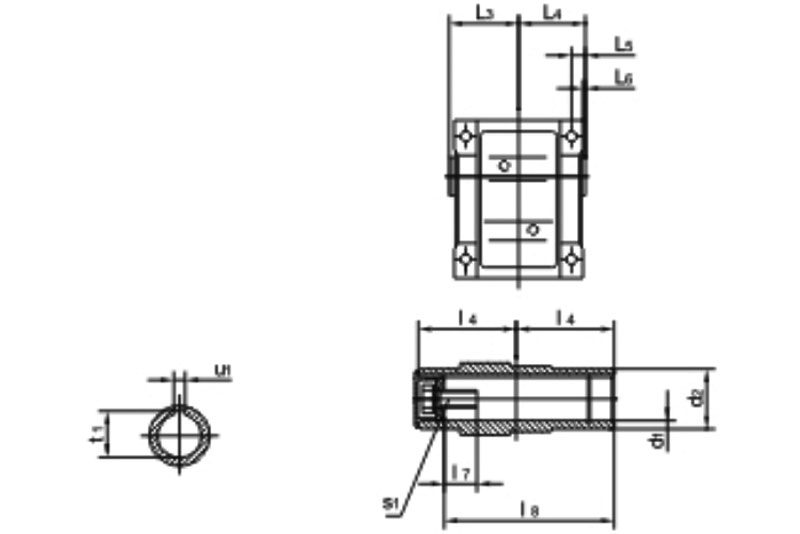

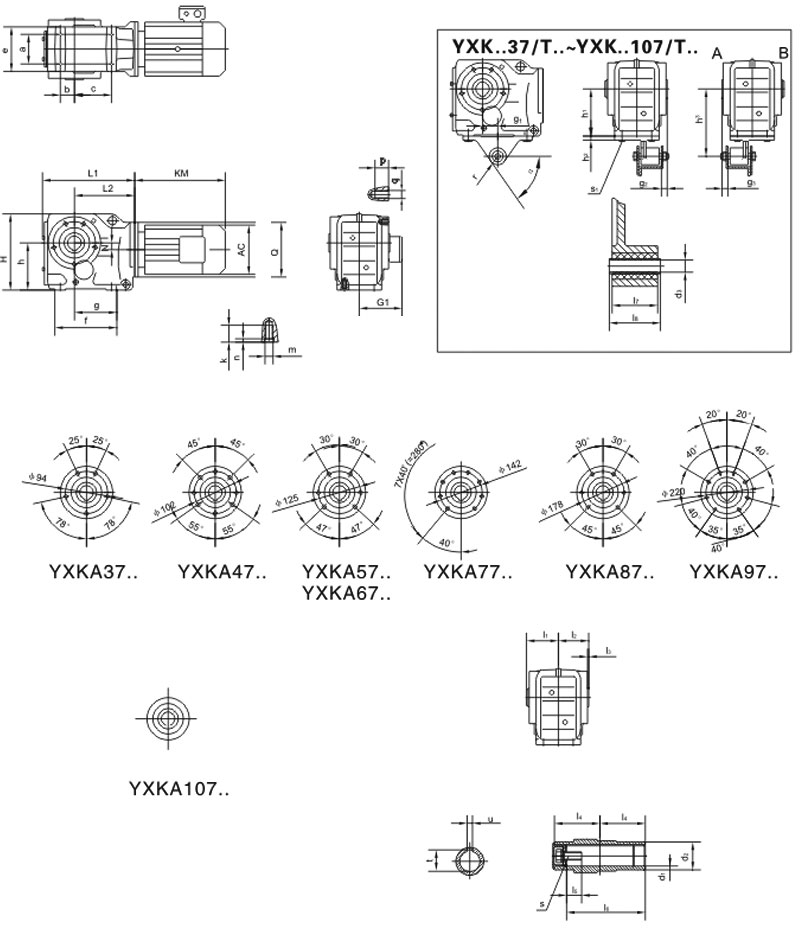

The shaft diameter of the K series helical gear motor directly determines the torque load-bearing capacity. According to the principle of mechanical transmission, the shaft diameter is positively correlated with the torque. Taking common models such as YXK37 - YXK157 as an example, the shaft diameter sizes (d, d1, d2) of different specifications correspond to different torque bearing ranges. If the shaft diameter is too small, the shaft is prone to deformation or even breaking under high load conditions, resulting in failure of power transmission.

From the perspective of material mechanics, the shaft diameter affects the torsional cross-section modulus, and a larger shaft diameter can reduce stress per unit area to ensure that the motor can output power stably under high loads. For example, in heavy-duty conveying equipment, the adapted shaft diameter size is the basis for maintaining the efficient operation of the equipment, otherwise the production efficiency may be affected by poor power transmission.

2. The influence of shaft diameter size on installation stability

The degree of matching the shaft diameter and the equipment interface is directly related to the installation stability. The specifications of the input shaft or connecting parts of various mechanical equipment are different. If the shaft diameter of the K series helical gear motor does not match the equipment interface, it will not only be difficult to install, but will also cause vibration and noise during operation, and even loosening and damage to the parts.

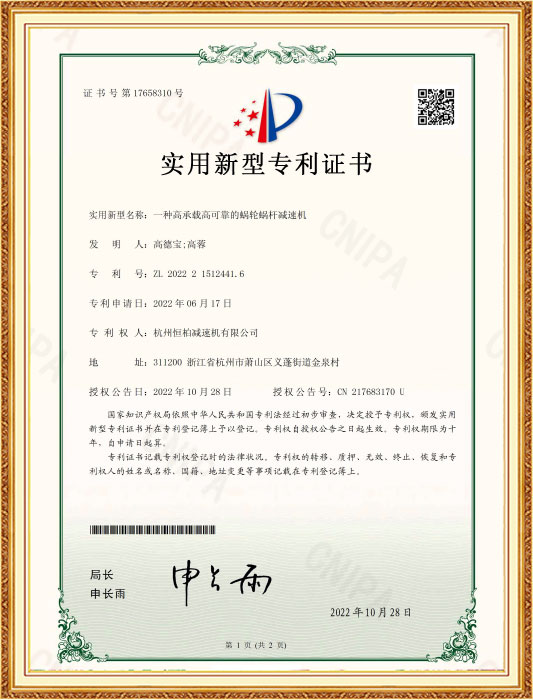

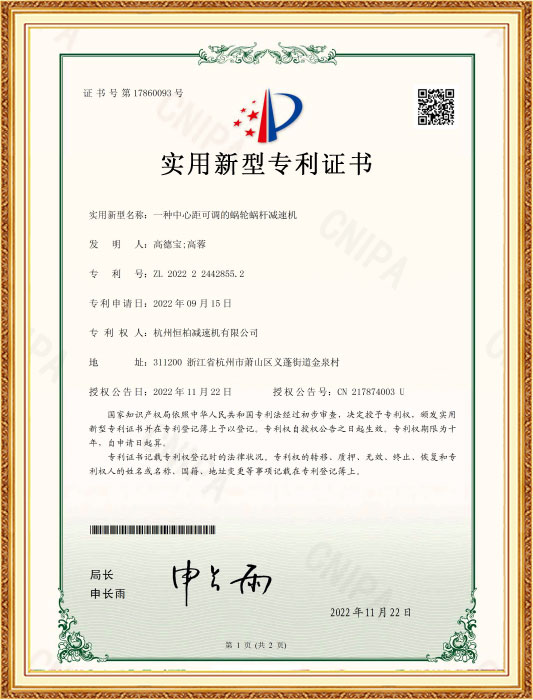

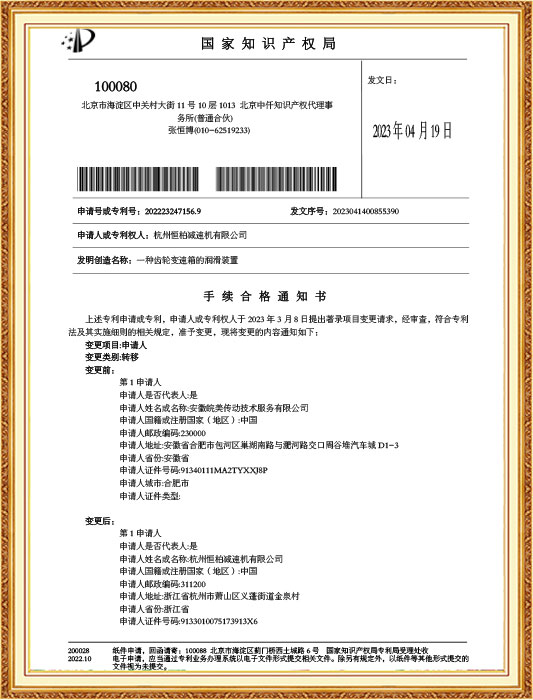

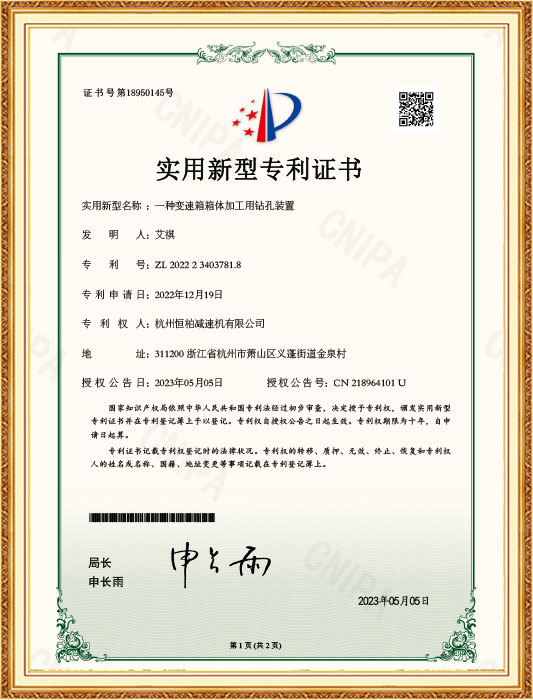

In order to meet different equipment needs, some companies such as Hangzhou Hengbai Reducer Co., Ltd., relying on their strong R&D team, can customize and produce motors that meet special installation requirements based on drawings or samples provided by customers, ensuring that the shaft diameter is perfectly adapted to the equipment interface and improving installation stability and reliability.

3. Shaft diameter and equipment service life

The adaptive shaft diameter size is the key to extending the service life of K series helical gear motors and supporting equipment. When the shaft diameter does not match the equipment requirements, the shaft is subjected to uneven stress and accelerates wear, which will also affect the motor's internal gears, bearings and other components, shorten the life of the transmission system.

Manufacturing accuracy and surface quality have a significant impact on shaft diameter performance. The high-quality K series helical gear motors are extremely strict in shaft diameter processing. For example, Hangzhou Hengbai Reducer Co., Ltd. has its own casting factory and CNC processing factory. It controls the entire process from raw materials to finished products, and cooperates with advanced testing equipment to ensure that key parameters such as shaft diameter and size meet high quality standards and ensure long-term and stable operation of the equipment.

The shaft diameter of K series helical gear motor has a profound impact on equipment adaptability from the dimensions of power transmission, installation stability, equipment service life, etc. In actual applications, enterprises need to reasonably choose shaft diameter and size based on equipment operation needs. At the same time, they can use customized services from enterprises with R&D and production capabilities to achieve efficient and stable operation of equipment.

English

English 中文简体

中文简体 Español

Español