What Are the Application Scenarios of S Series Helical Gear Motor?

Industrial Automation and Manufacturing

The S series helical gear motor plays a vital role in automated production systems. These motors are commonly integrated into conveyor belts to ensure smooth material transportation across factory floors. Their precision engineering makes them suitable for packaging equipment where consistent speed control is required for sealing and labeling operations. In assembly line applications, the motors provide reliable torque transmission for robotic arms and precision assembly stations, enhancing production efficiency while maintaining low noise levels.

Food and Beverage Industry

Within food processing facilities, the S series helical gear motor demonstrates excellent performance in hygienic environments. These motors drive mixers and blenders to achieve uniform consistency in food products without excessive vibration. Bottling and canning lines benefit from their steady operation under continuous high-speed production demands. For bakeries and dough processing plants, the motors deliver the necessary torque for kneading and shaping operations while meeting strict sanitation requirements.

Material Handling and Logistics

Warehousing and logistics operations increasingly rely on S series helical gear motors for efficient material movement. These motors power crane and hoist systems, enabling safe lifting and lowering of heavy cargo. In automated storage facilities, they drive palletizers and stackers to organize goods systematically. The motors also serve as key components in automated guided vehicles (AGVs), ensuring precise navigation and load handling in smart warehouse environments.

Agricultural Machinery

Agricultural applications demand robust gear motors capable of withstanding harsh outdoor conditions. S series motors are employed in irrigation systems to operate water pumps efficiently across large fields. Harvesting equipment utilizes these motors to power cutting mechanisms and grain threshers. Feed mixing stations incorporate them to maintain consistent blending of livestock nutrition, demonstrating their versatility in farm operations.

Construction and Heavy Machinery

The construction sector requires durable power transmission solutions for demanding applications. S series helical gear motors are integral to concrete mixers, providing the necessary torque to blend heavy construction materials effectively. Excavators and mobile cranes utilize these motors for reliable lifting and digging functions. In road construction, vibratory compactors equipped with these motors ensure proper soil and asphalt compaction for stable surfaces.

Renewable Energy Sector

As sustainable energy solutions advance, S series helical gear motors contribute to efficient power generation. Wind turbine systems incorporate these motors in pitch control mechanisms to optimize blade angles according to wind conditions. Solar power installations use them in tracking systems to maintain proper panel orientation toward sunlight throughout the day, maximizing energy capture.

Why Choose Hengbai's S Series Helical Gear Motors?

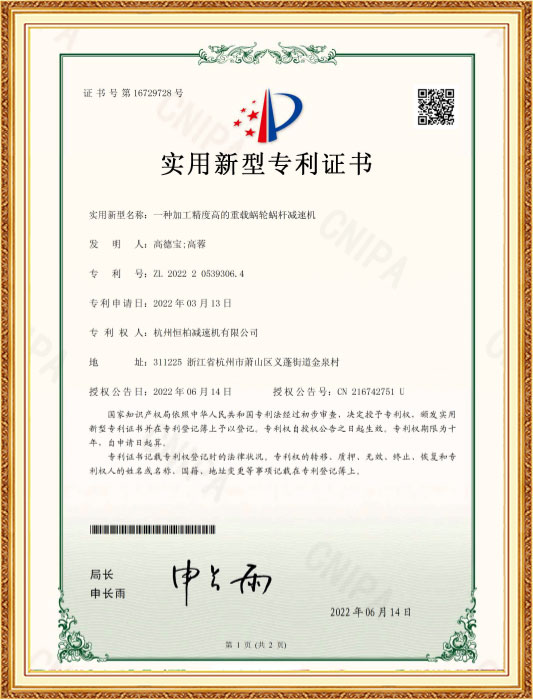

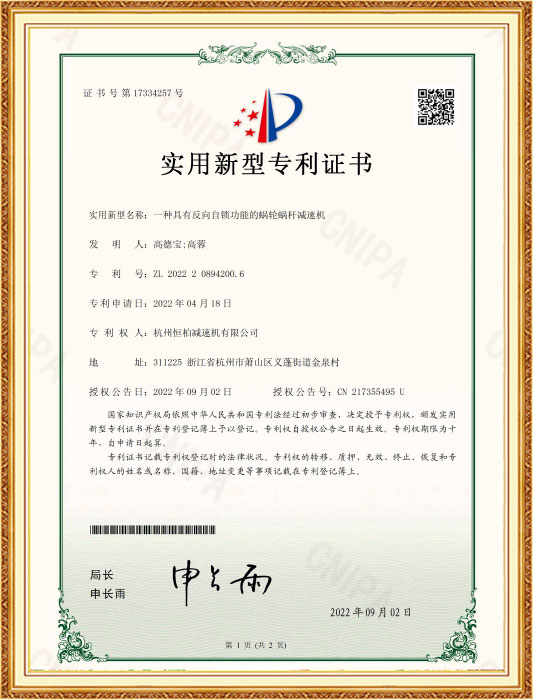

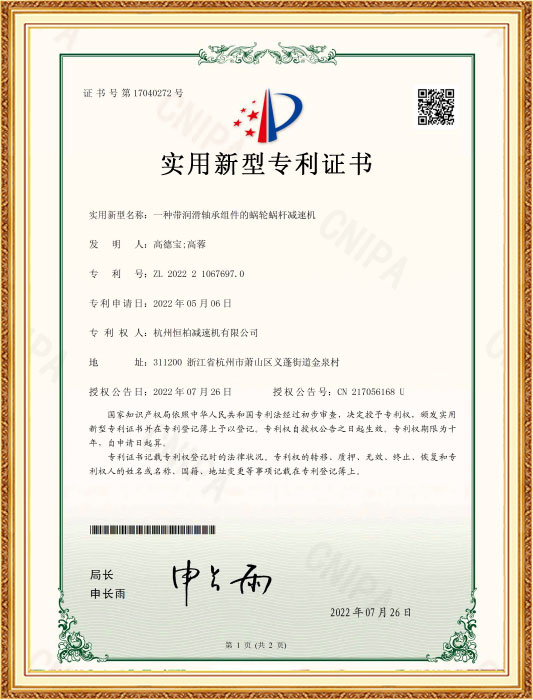

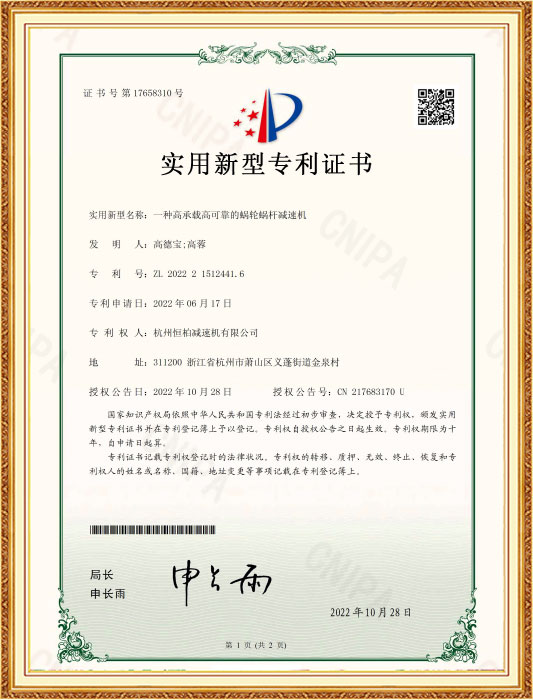

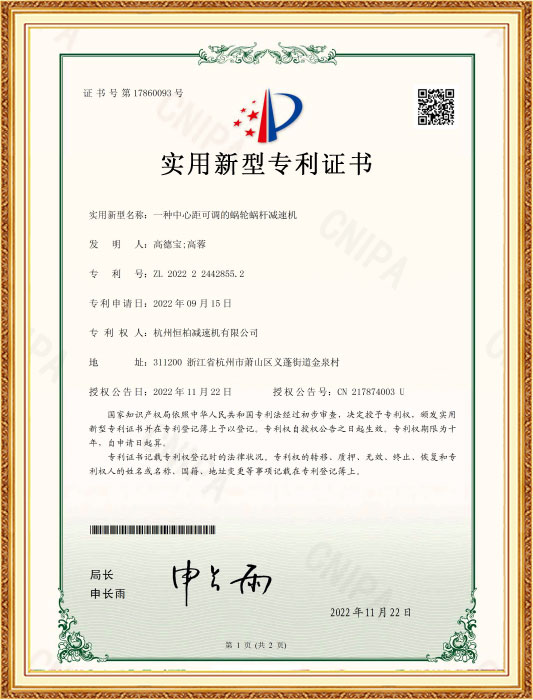

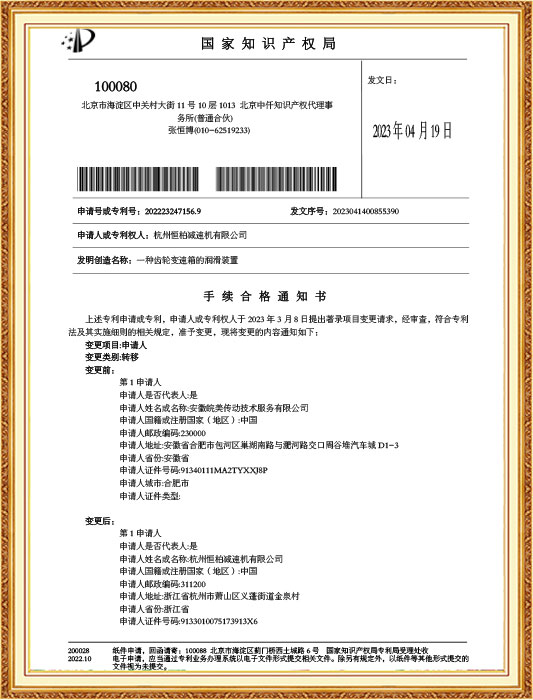

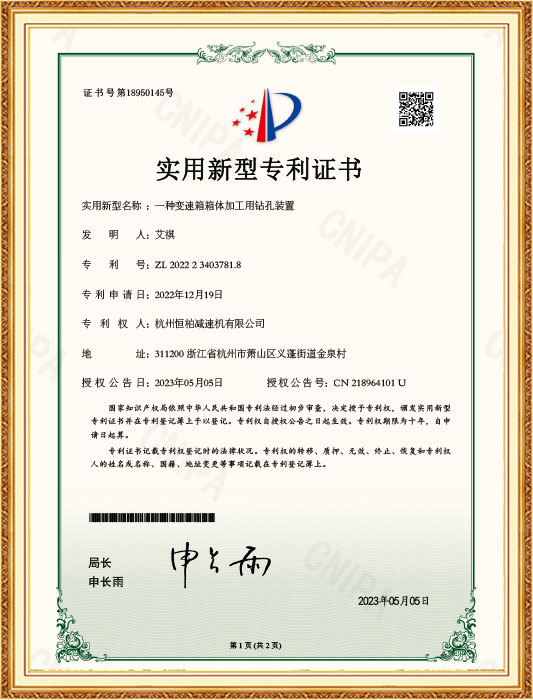

Hangzhou Hengbai Reducer Co., Ltd. brings over three decades of expertise in gear motor manufacturing since its establishment in 1988. The company's S series products meet rigorous international standards, holding certifications including CE, ROHS, and ISO quality management systems. With exports reaching more than 30 countries across Europe, America, and Asia, Hengbai has established itself as a globally trusted provider of industrial transmission solutions.

The company maintains a strong commitment to technological innovation and product refinement. Its professional engineering team and advanced manufacturing facilities ensure reliable performance across all S series applications. Comprehensive after-sales support further enhances customer experience, making Hengbai a preferred partner for businesses worldwide.

The S series helical gear motor serves as a fundamental component across diverse industrial sectors, from automated production to renewable energy systems. Its combination of robust construction, operational efficiency, and adaptability makes it indispensable for modern industrial applications.

English

English 中文简体

中文简体 Español

Español