How do the torque output and speed of the F series helical gear motor match different working conditions?

Differences in working conditions give rise to diverse demands

From heavy-duty fields such as metallurgy and mining to precision manufacturing industries such as 3C electronics and medical devices, the working conditions and challenges faced by the F series helical gear motors are different. In the steel rolling production line of the metallurgical industry, huge steel billets require the motor to instantly output up to tens of thousands of Newton meters of torque to drive the rollers to complete the rolling of the steel plate. At this time, the speed is usually controlled at a low level to avoid the surface quality of the steel plate from being reduced due to excessive speed; in the precision assembly link of the 3C electronics production line, the motor needs to run at a high speed of thousands of revolutions per minute while maintaining micron-level positioning accuracy, which requires extremely high torque stability. For example, a semiconductor chip packaging device requires the F series helical gear motor to continuously output stable torque at high speed to ensure that the chip handling robot arm completes the operation quickly and accurately. Any torque fluctuation may cause chip damage and cause significant losses.

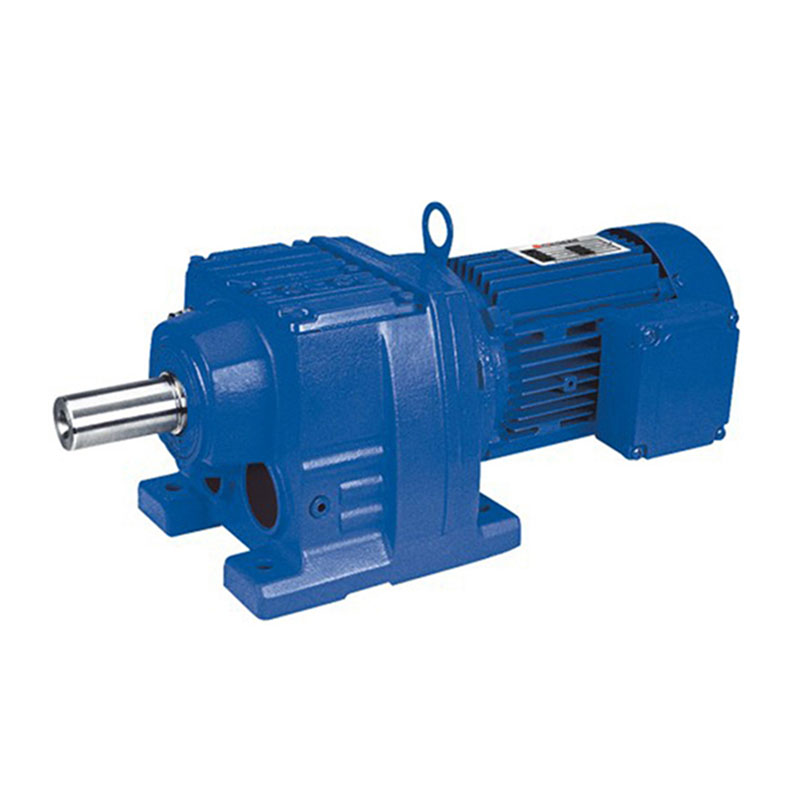

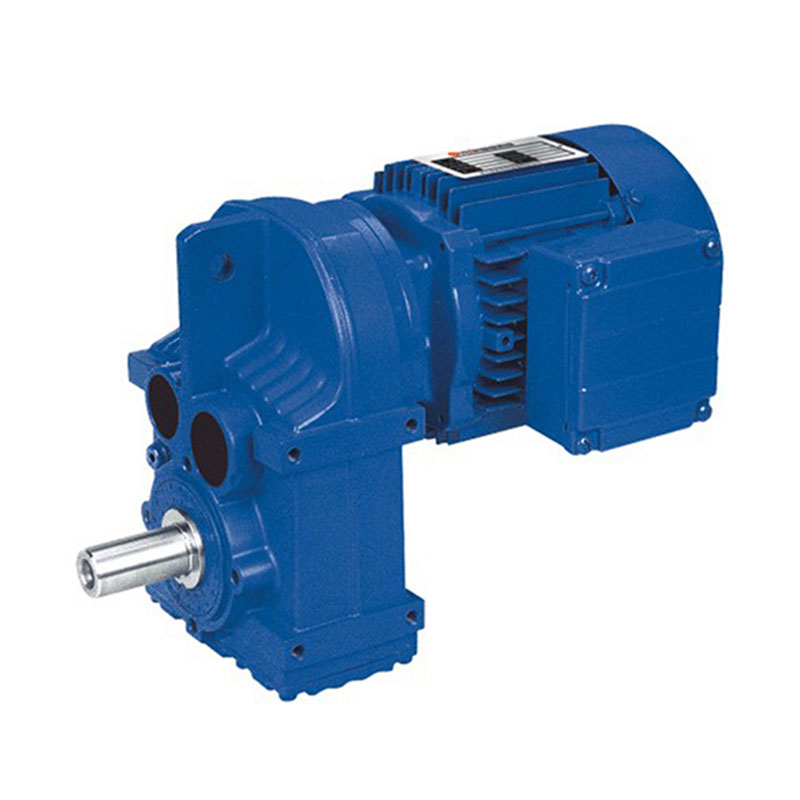

Core technical characteristics of the F series helical gear motor

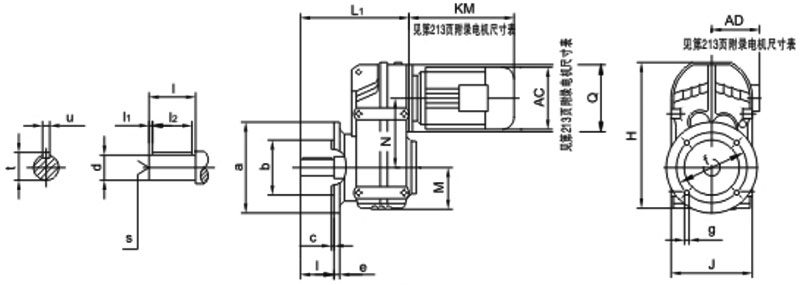

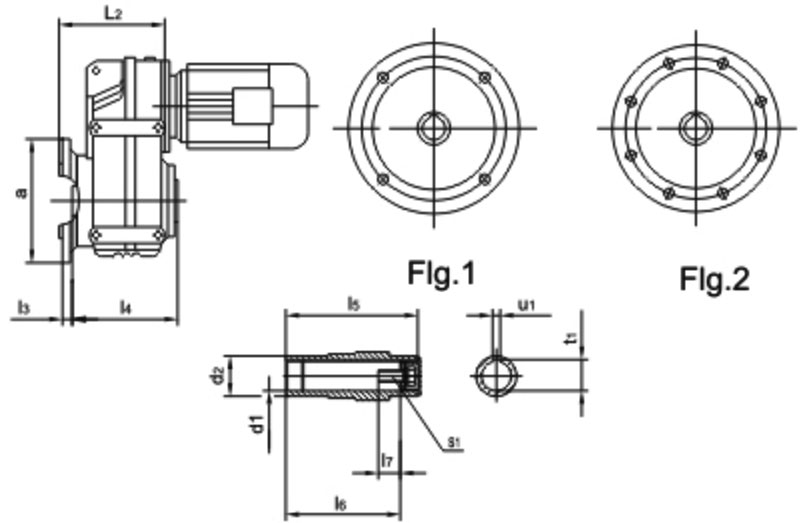

The excellent performance of the F series helical gear motor comes from its unique structural design and technological innovation. Its helical gear adopts involute tooth shape, which makes the meshing process smoother than spur gears, and can effectively reduce the impact and noise during the transmission process, while increasing the overlap and improving the load-bearing capacity. In terms of material selection, gears are usually made of high-strength alloy steel and are carburized and quenched. The surface hardness can reach HRC58-62, and the internal toughness is maintained, which not only ensures wear resistance but also enhances fatigue resistance. The motor housing is made of cast iron or aluminum alloy. After finite element analysis and optimization design, it has good rigidity and heat dissipation performance, can effectively suppress vibration, and ensure the stable operation of the motor under high load.

In terms of transmission efficiency, the F series helical gear motor has a transmission efficiency of more than 95% with its precise manufacturing process and optimized gear parameters. By adopting high-precision gear grinding technology, the gear tooth surface roughness Ra value can be controlled below 0.8μm, which greatly reduces friction loss. At the same time, the motor is equipped with a high-efficiency motor winding, which uses low-resistance electromagnetic wire and an optimized magnetic circuit design to further improve the overall efficiency of the motor. At the same power output, the energy consumption is reduced by 10% - 15%.

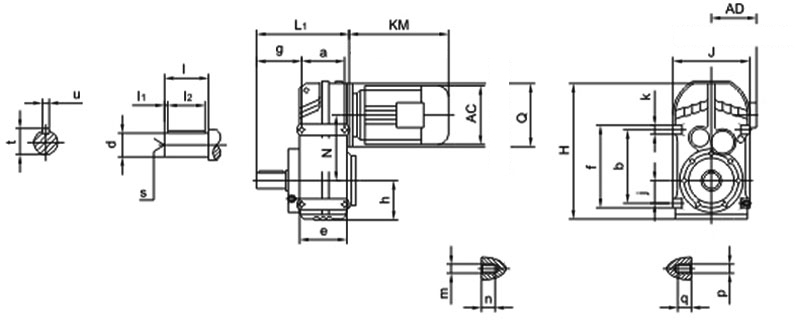

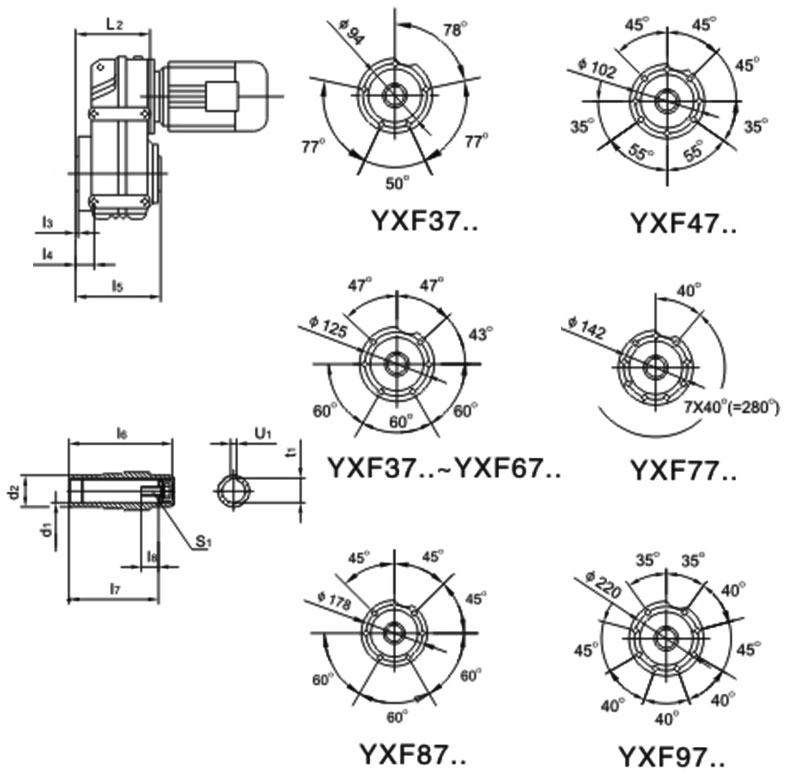

Precise matching strategy of torque and speed

To achieve the precise matching of torque and speed of F series helical gear motors, multiple factors need to be considered comprehensively. First, calculate the required torque according to the load characteristics. For inertial loads, the inertial torque during the start-up acceleration process needs to be considered; for friction loads, the torque required to overcome friction needs to be calculated. Secondly, determine the speed range in combination with process requirements, and refer to the speed-torque curve of the motor to select the best working point. For example, in belt conveyor applications, if the conveying distance is long and the material is heavy, a motor model with high torque and low speed needs to be selected; if the conveying distance is short and fast conveying is required, a model with high speed and medium torque needs to be selected.

In addition, by configuring different reduction ratios, the output torque and speed of the motor can be flexibly adjusted. The F series helical gear motors offer a variety of reduction ratios, ranging from 5:1 to 500:1, which can be customized by users according to actual needs. Some high-end models are also equipped with an intelligent control system that can monitor the operating status of the motor in real time, automatically adjust the torque and speed according to load changes, and achieve energy-saving and efficient operation.

Enterprises help the development of the industry

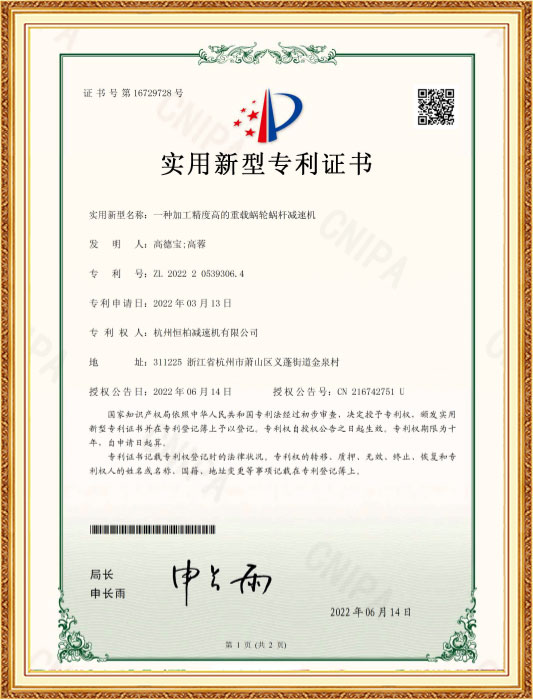

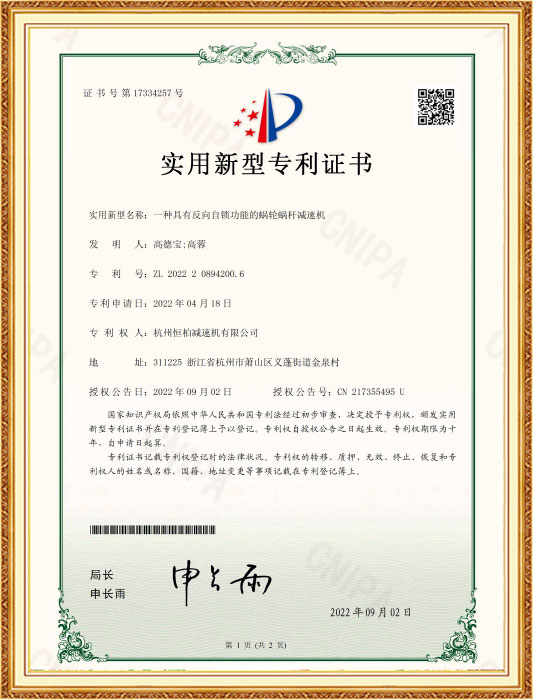

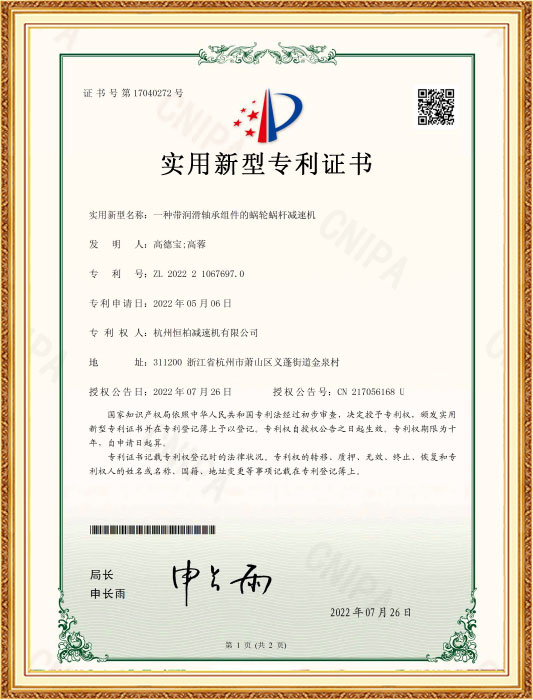

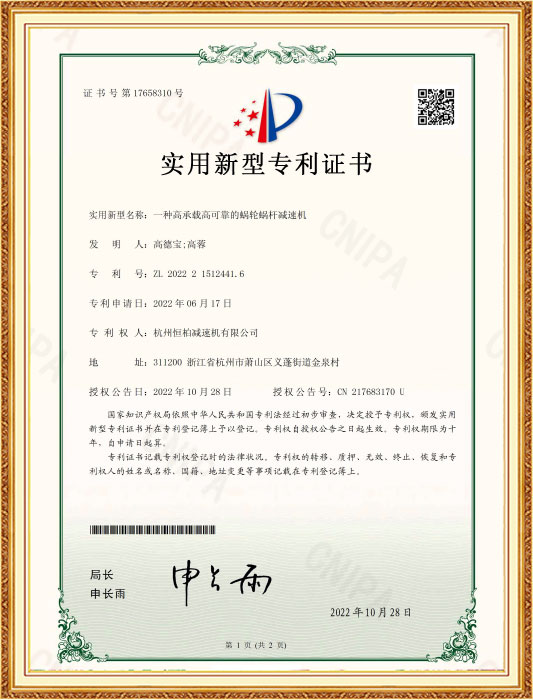

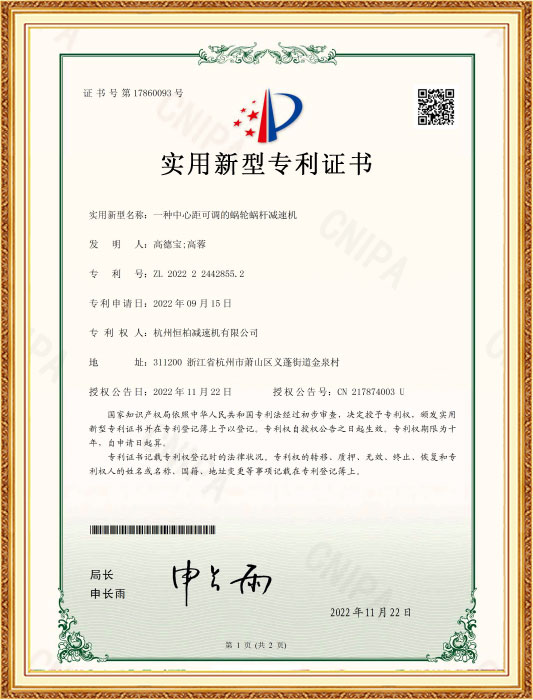

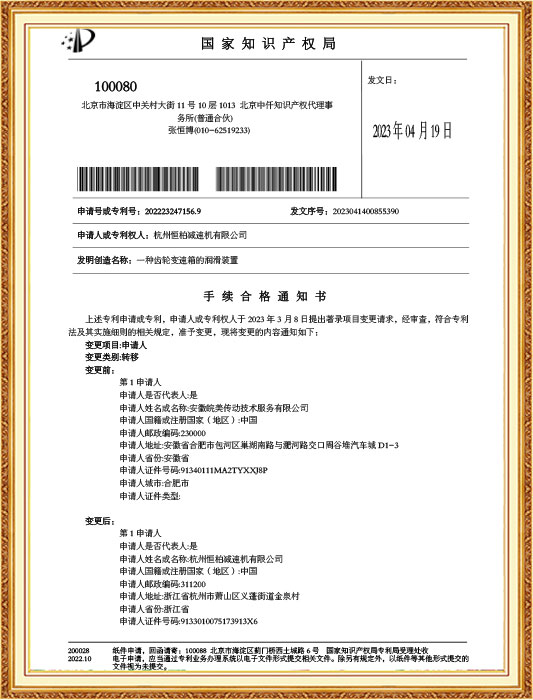

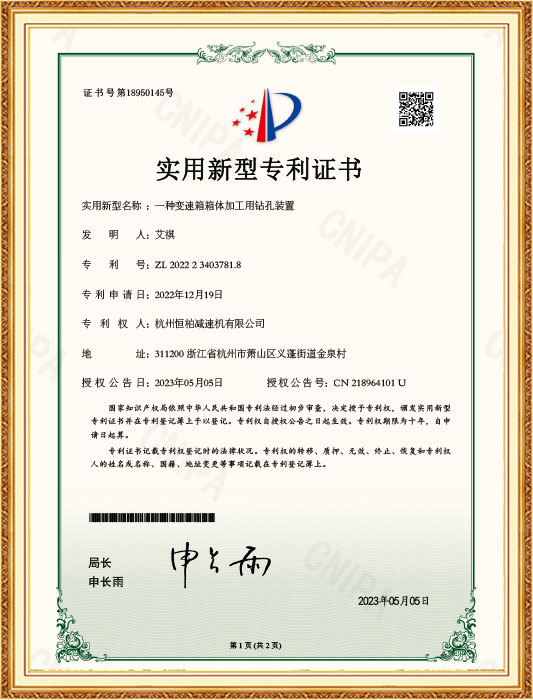

Hangzhou Hengbai Reducer Co., Ltd. has played an important role in the research and development and application promotion of the F series helical gear motors. As an old-fashioned enterprise in the industry founded in 1988, it has continued to deepen its presence in the fields of gearbox, reducer, and motor manufacturing with its professional technical team and advanced processing equipment. The F series helical gear motors developed by the company have obtained multiple certifications such as quality management system, ROHS, CE, etc. through continuous optimization of design and strict quality control. The products are sold well in China and exported to more than 30 countries and regions such as the United States, Germany, and the United Kingdom.

Adhering to the concept of "innovation and improvement", Hangzhou Hengbai has developed customized solutions for the needs of different industries. In the automation transformation project of a certain automotive parts foundry, Hangzhou Hengbai customized a large reduction ratio F series helical gear motor for its sand casting equipment to meet its requirements for high torque and low speed of the motor, and optimized the heat dissipation structure to ensure that the motor can operate stably in harsh environments with high temperature and high dust, effectively improving production efficiency and equipment reliability.

With the in-depth promotion of Industry 4.0, the requirements for the intelligence and efficiency of the F series helical gear motor are becoming more and more urgent. In the future, the industry will continue to innovate in the direction of digital control and adaptive adjustment of motors to provide smarter and more reliable power solutions for industrial production.

English

English 中文简体

中文简体 Español

Español