How do NMRV Worm Gear Speed Reducers with different speed ratios affect the running stability of equipment?

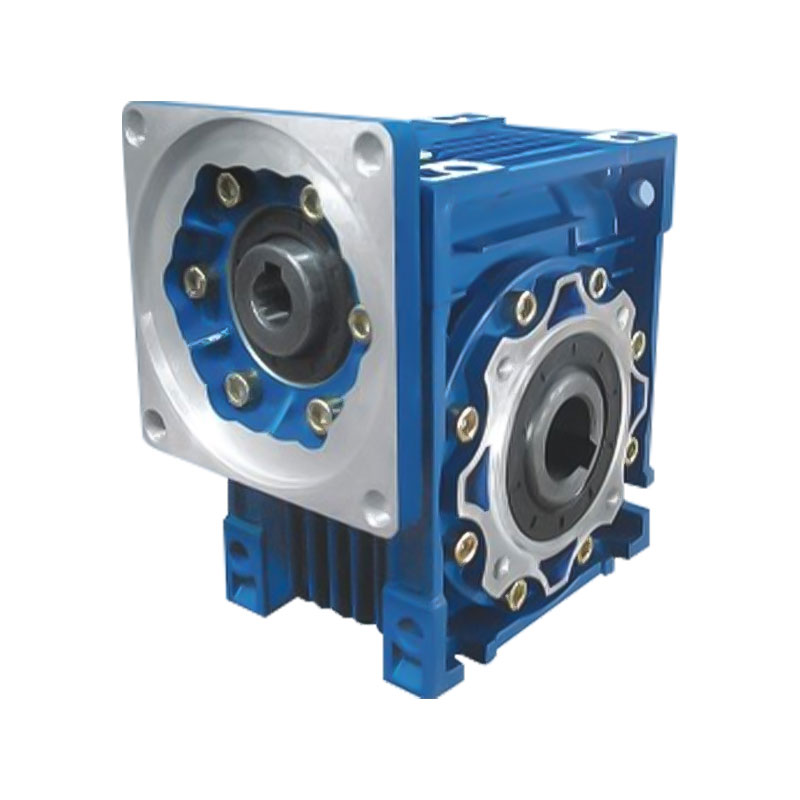

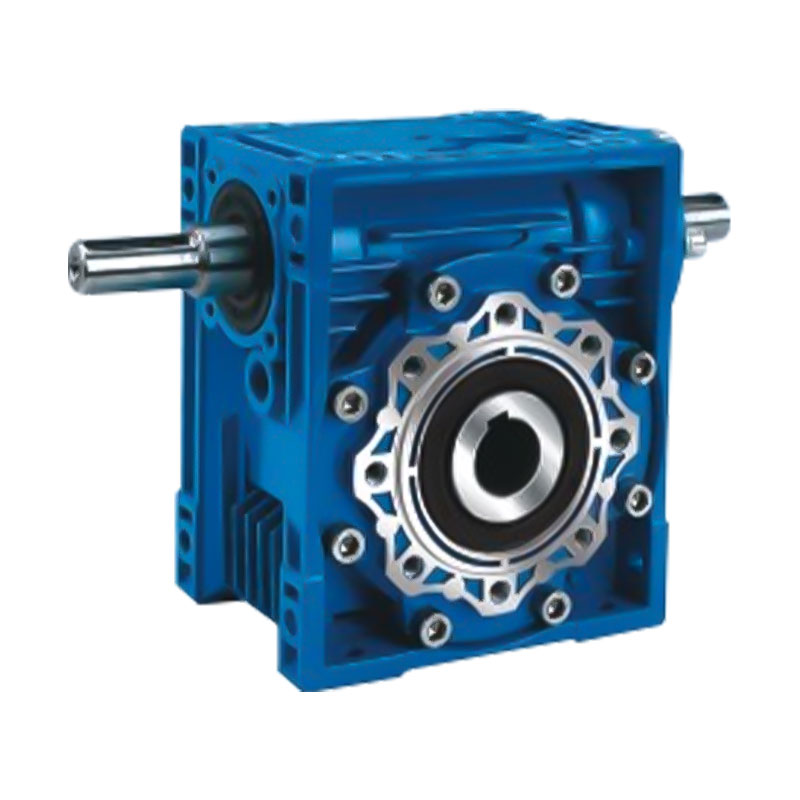

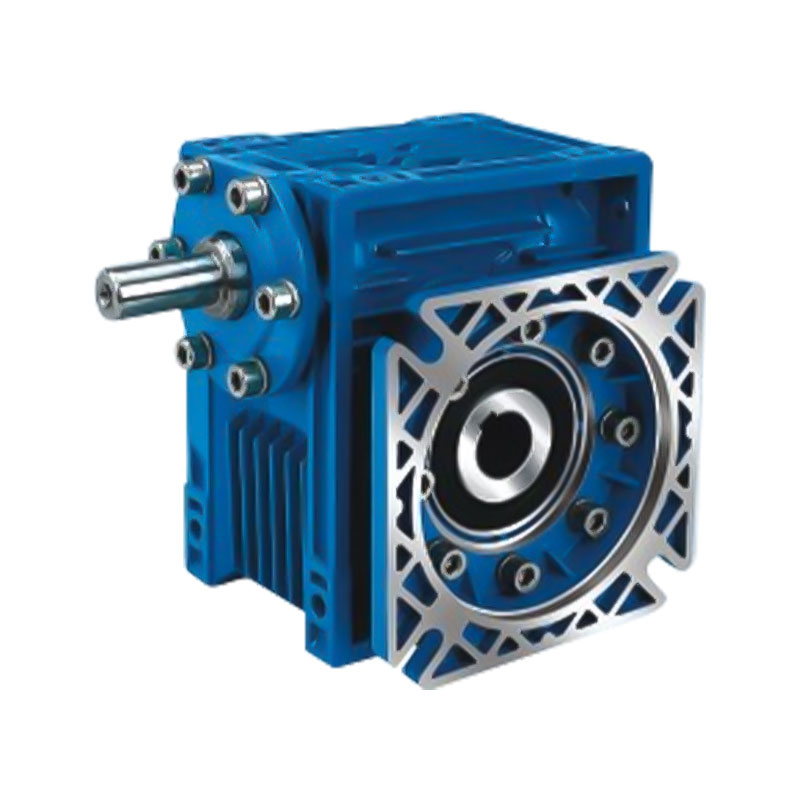

In the field of mechanical transmission, NMRV Worm Gear Speed Reducer is widely used in many industries such as automated production lines, conveying equipment, and packaging machinery due to its compact structure and large transmission ratio. However, NMRV Worm Gear Speed Reducer with different speed ratios have a significant impact on the running stability of equipment.

1. Direct impact of speed ratio on output characteristics

Speed ratio is one of the core parameters of NMRV Worm Gear Speed Reducer, which directly determines the proportional relationship between input speed and output speed. Generally speaking, the larger the speed ratio, the lower the output speed, but the output torque will increase accordingly. For the running stability of equipment, the selection of different speed ratios needs to fully consider the actual working conditions. In application scenarios that require high torque and low speed, such as heavy material conveying or extrusion molding equipment, selecting a larger speed ratio NMRV Worm Gear Speed Reducer can provide sufficient power output to avoid equipment jamming or even shutdown due to insufficient torque, thereby effectively improving the running stability. Through the precise worm gear design and the selection of high-quality materials, it is ensured that the torque transmission can still be maintained smoothly under high-speed ratio conditions, reducing equipment vibration and noise.

2. The relationship between speed ratio, transmission efficiency and thermal management

On the contrary, in scenarios with high speed response requirements, such as material sorting equipment on automated assembly lines, NMRV Worm Gear Speed Reducer with smaller speed ratios can achieve faster speed output to meet the needs of fast action. However, it should be noted that a smaller speed ratio may be accompanied by a reduction in output torque. If the equipment load is too large, it may cause the reducer to overload and affect stability. Suppliers with professional technical teams, such as Hangzhou Hengbai Reducer Co., Ltd., will provide personalized selection solutions based on the specific working conditions of customers, and recommend the most suitable speed ratio by accurately calculating parameters such as load and speed to ensure stable operation of the equipment.

In addition, the speed ratio will also affect the transmission efficiency and heat generation of the NMRV Worm Gear Speed Reducer. Usually, when the speed ratio is too large, the friction loss in the transmission process increases, which may cause the reducer temperature to rise. Long-term high-temperature operation will accelerate the wear of components and reduce the stability and service life of the equipment. During the product development process, special lubrication processes and heat dissipation designs are used, such as optimizing the tooth structure of the worm gear and selecting high-performance lubricating grease to effectively reduce the friction coefficient and control the operating temperature, ensuring long-term stable operation of the equipment even under high speed ratio conditions.

3. The key role of precision manufacturing process in stability

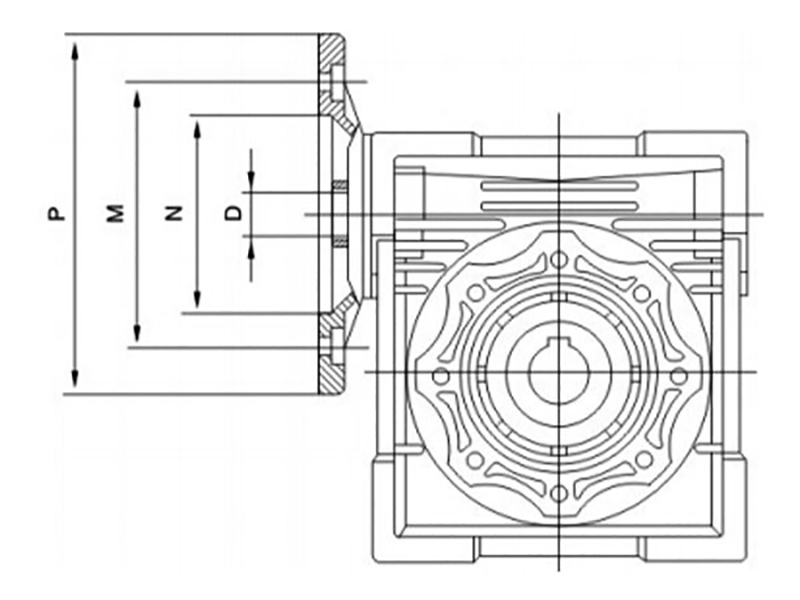

From the perspective of manufacturing process, as a professional manufacturer of reducers, Hangzhou Hengbai Reducer Co., Ltd. has accumulated profound insights in this field with years of technical accumulation and rich experience. HENGBAI strictly controls the production quality of NMRV Worm Gear Speed Reducer. Advanced processing equipment ensures high-precision manufacturing of worm gears, making the tooth surface contact more uniform and reducing impact and vibration during transmission. Scientific management systems and full-process monitoring by professional technicians ensure that each product meets high standards. At the same time, the company has obtained a number of international certifications, such as CE certification, which means that its products have reached international standards in terms of safety and reliability, providing authoritative endorsement for the stability of equipment operation.

English

English 中文简体

中文简体 Español

Español