What is the correlation between the speed ratio range and transmission efficiency of R series helical gear reducer motors?

Basic concepts of speed ratio range and transmission efficiency

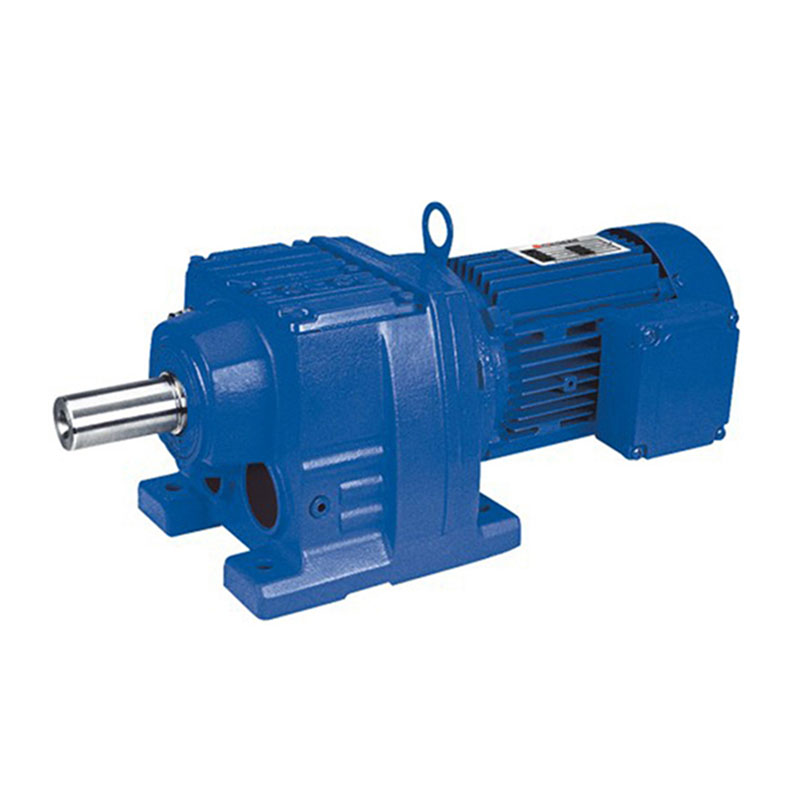

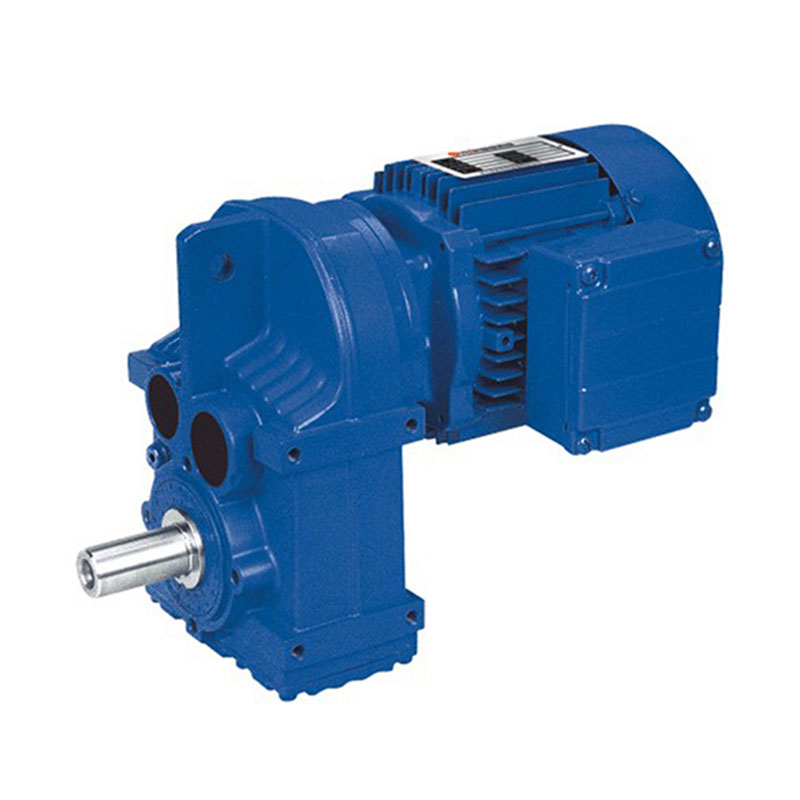

Speed ratio (reduction ratio) refers to the ratio of the input shaft speed of the reducer motor to the output shaft speed, which determines the output torque and speed of the motor. R series helical gear motors usually have a wide range of speed ratios, such as from 5:1 to 200:1, or even higher, to meet the needs of different working conditions.

Transmission efficiency refers to the loss of the gear reducer during the energy transfer process, which is usually expressed in percentage. The transmission efficiency of helical gear reducer motors is generally above 90%, which is more advantageous than worm gear reducer (efficiency is about 70%-80%).

Effect of speed ratio range on transmission efficiency

The speed ratio increases, and the efficiency may decrease

In R series helical gear motor, the higher the speed ratio means the number of gear meshing or the number of transmission stages (such as multi-stage deceleration). Each stage of transmission will be accompanied by certain energy loss (friction, heating, etc.), so the larger the speed ratio, the slightly lower the overall transmission efficiency.

Single-stage vs. Multi-stage deceleration

Single-stage deceleration (speed ratio is usually between 5:1 and 20:1) Due to the few gear meshing times, the transmission efficiency is high, usually up to more than 95%.

Multi-stage deceleration (speed ratio exceeds 30:1) Due to the use of multiple gear transmission, although it can provide a larger reduction ratio, the efficiency will be reduced by 1%-3% for each additional transmission.

The influence of gear processing accuracy and material

Even if the speed ratio is the same, there may be differences in the efficiency of the reducer motors for different manufacturing processes. For example, the gear pair using high-precision grinding technology and high-quality alloy steel can effectively reduce friction loss and improve transmission efficiency.

How to balance speed ratio and efficiency choice

In practical applications, users need to weigh the speed ratio and efficiency according to specific needs:

High torque and low speed applications (such as conveyors, mixing equipment): Higher speed ratios can be selected, which are better than other types of reducers (such as worm gears and worms) even if they are slightly less efficient.

High efficiency demand scenarios (such as automated production lines, precision equipment): Single-stage or double-stage deceleration schemes are preferred to ensure high energy utilization.

The technical advantages of excellent manufacturers

Taking the industry-leading Hangzhou Hengbai Reducer Co., Ltd. as an example, its R series helical gear reduction motor adopts advanced CNC machining center and precision inspection equipment to ensure gear meshing accuracy, so that high transmission efficiency can be maintained within a wide speed ratio range. In addition, its own foundry and R&D team can customize optimization solutions according to customer needs, such as improving gear wear resistance through special heat treatment processes, further reducing efficiency losses in long-term use.

The speed ratio range of R series helical gear motor has a certain negative correlation with transmission efficiency, but by optimizing gear design, improving manufacturing accuracy and selecting high-quality materials, efficiency losses can be minimized. When selecting a model, users should choose the most matching reduction ratio solution based on the equipment load, speed requirements and energy efficiency standards. Manufacturers with complete industrial chain and technical strength (such as Hengbai) can provide more reliable solutions.

English

English 中文简体

中文简体 Español

Español