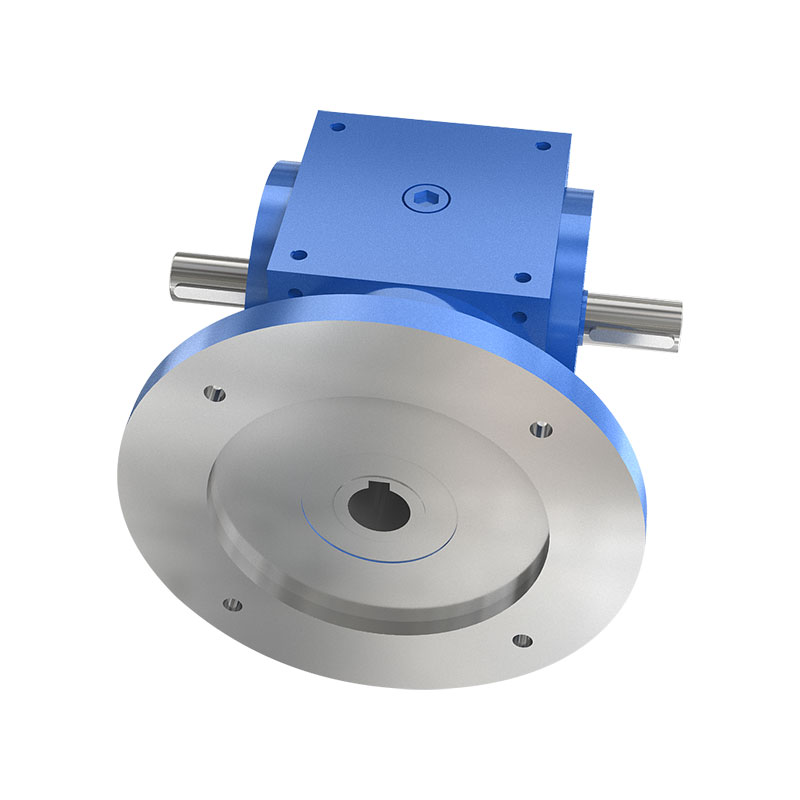

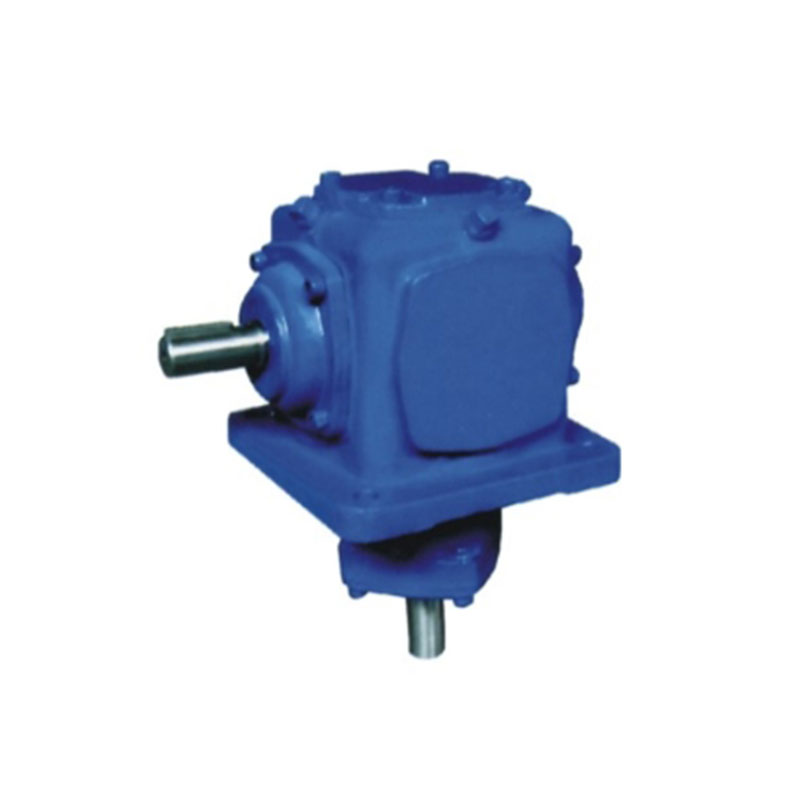

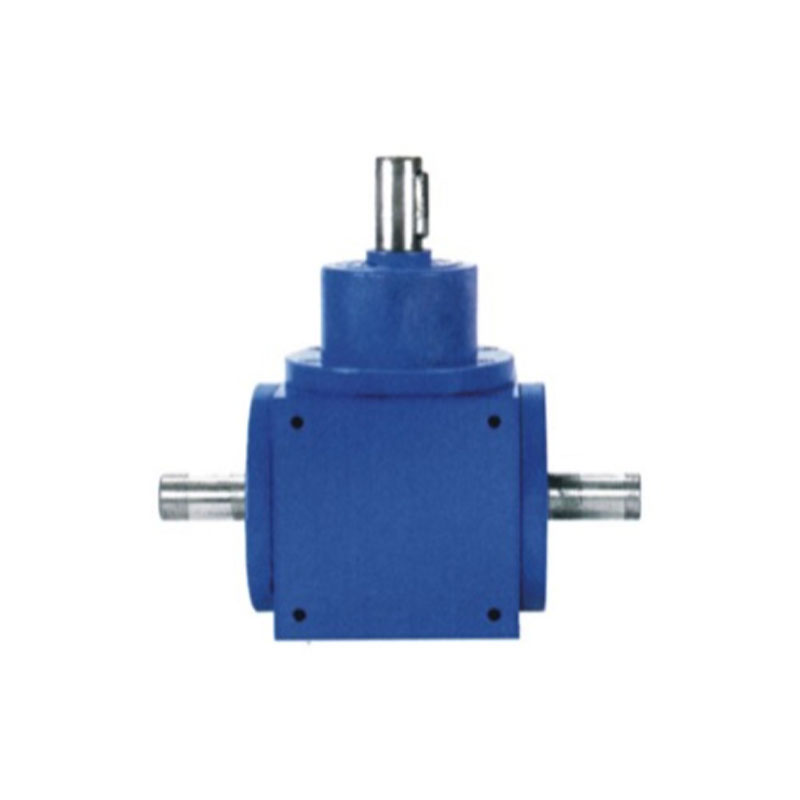

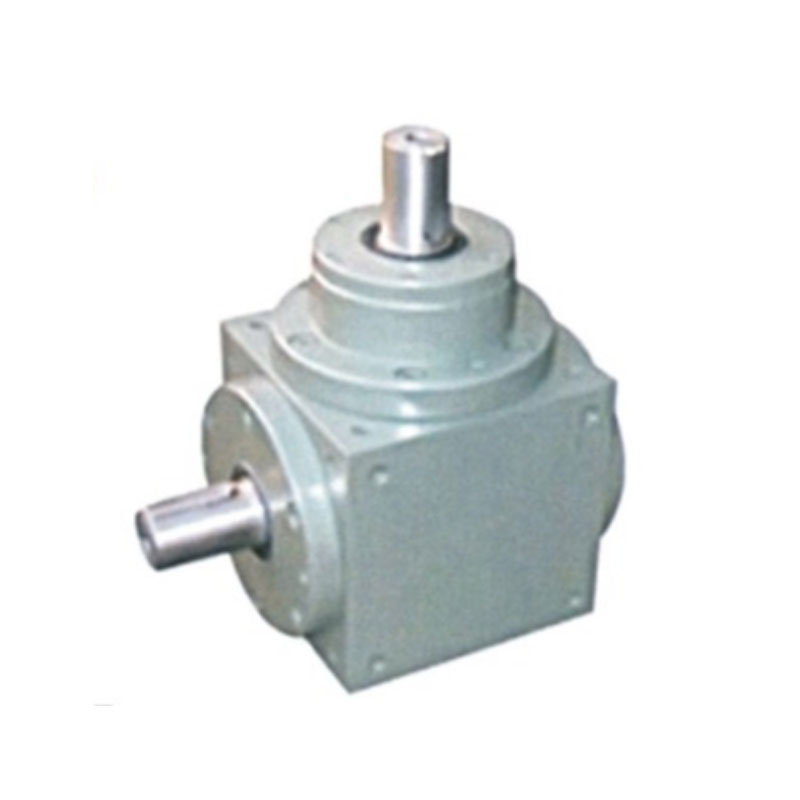

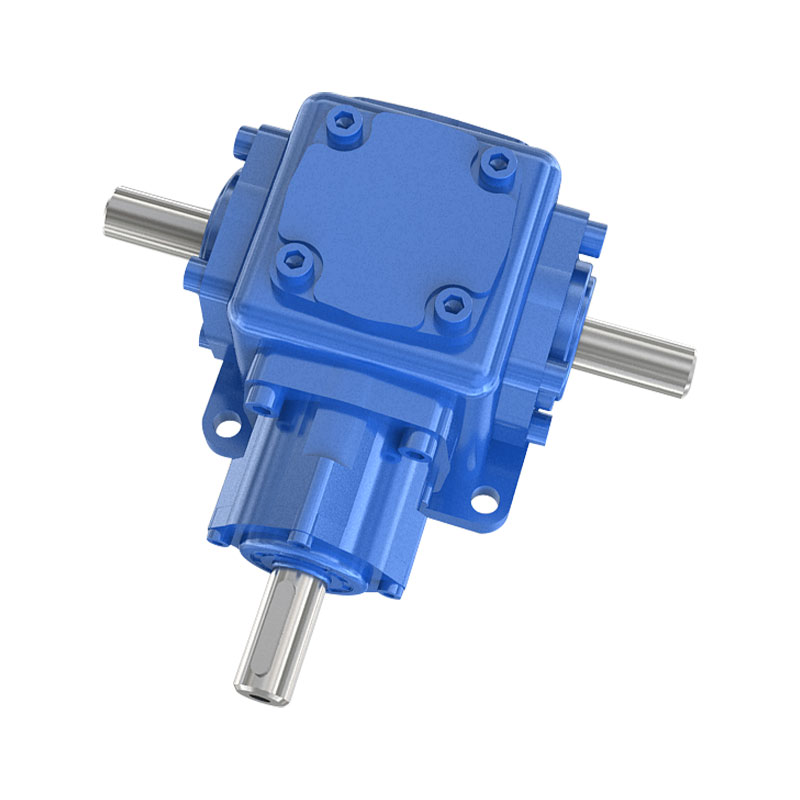

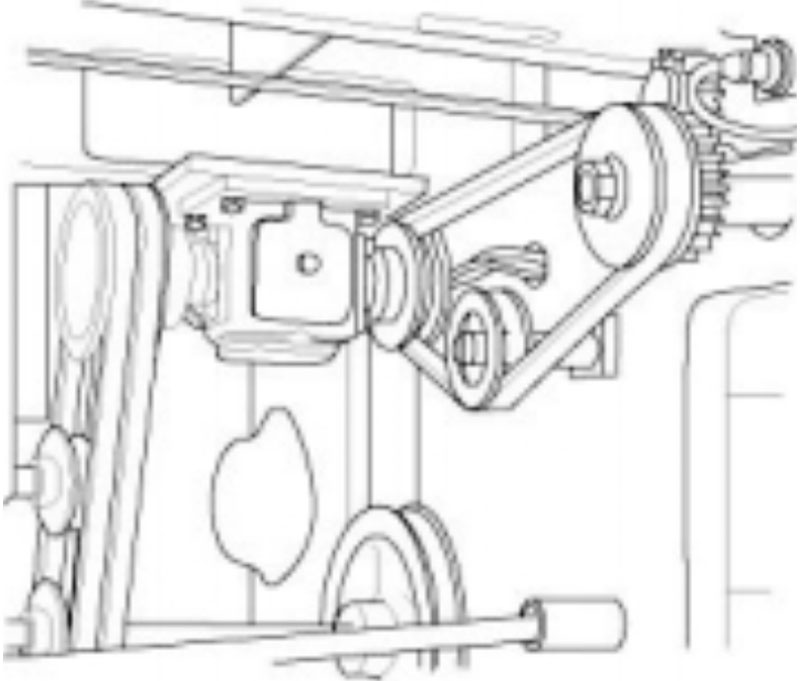

Key Applications of T Series Steering Spiral Bevel Gearboxes in Agricultural and Construction Equipment

1. Agricultural Machinery: Precision and Durability in Harsh Conditions

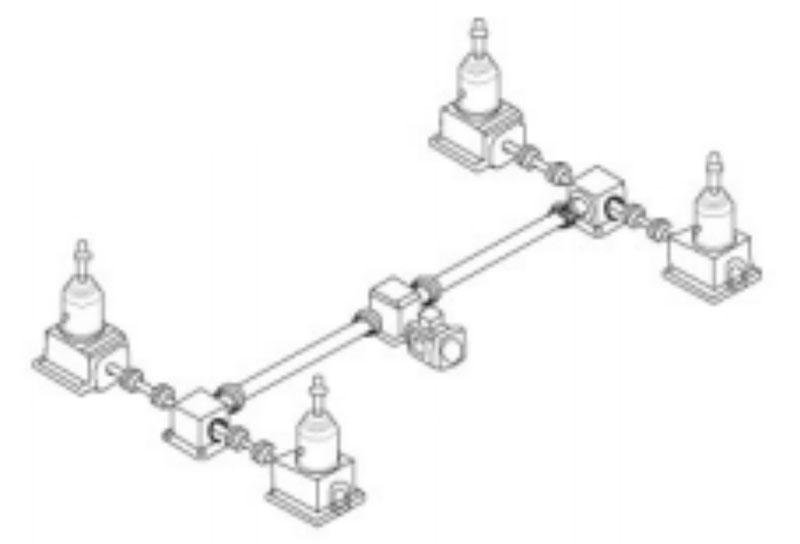

Tractors & Harvesters: T Series steering spiral bevel gearbox provide reliable torque transmission and smooth steering control, essential for row-crop farming and uneven terrain.

Sprayers & Planters: The compact design and high efficiency ensure accurate maneuverability for precision agriculture operations.

Advantage: Spiral bevel gears reduce backlash, enhancing responsiveness in tight turns.

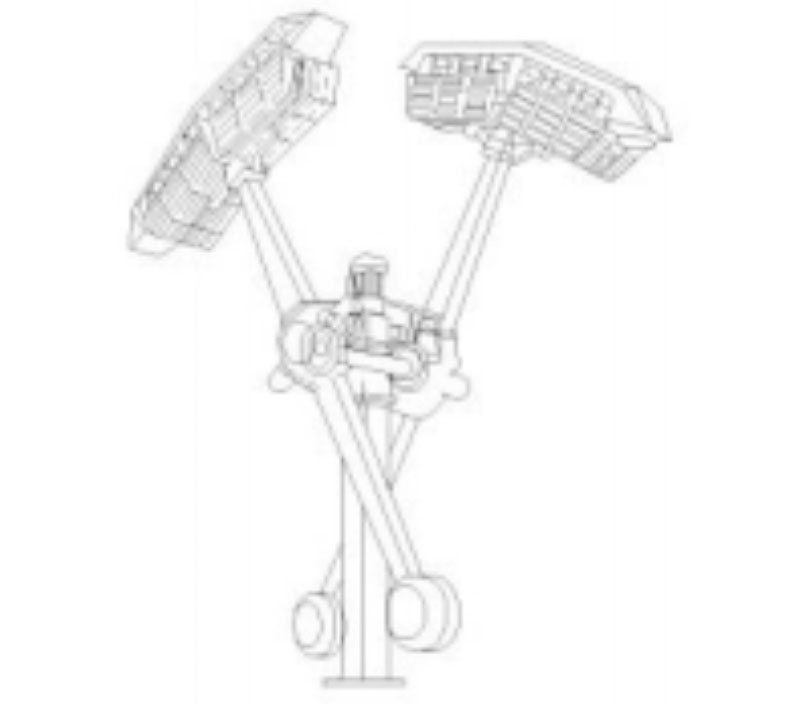

2. Construction Equipment: Heavy-Duty Performance

Skid Steer Loaders: Robust T Series gearboxes handle high axial/radial loads during frequent directional changes.

Excavators & Bulldozers: Optimized for slow-speed, high-torque steering in rugged environments.

Key Feature: Sealed housings protect against dust, debris, and moisture—critical for construction sites.

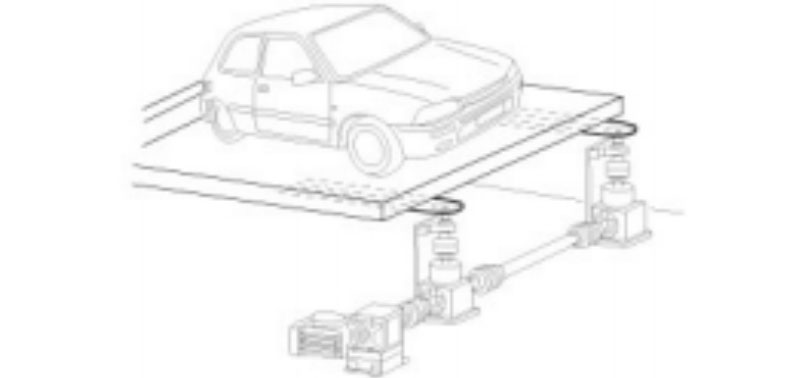

3. Material Handling & Off-Road Vehicles

Forklifts: Ensures precise steering in confined warehouse spaces.

Mining Vehicles: Built to endure extreme loads and vibrations with minimal maintenance.

4. Why T Series?

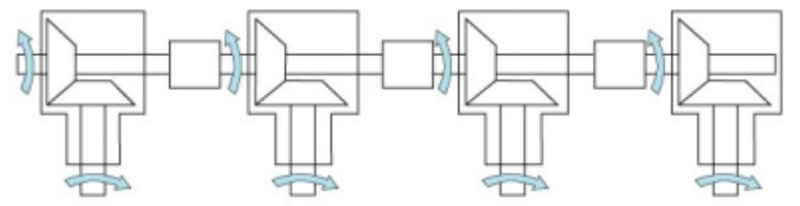

Spiral Bevel Gear Design: Smother engagement, higher load capacity, and reduced noise vs. straight bevel gears.

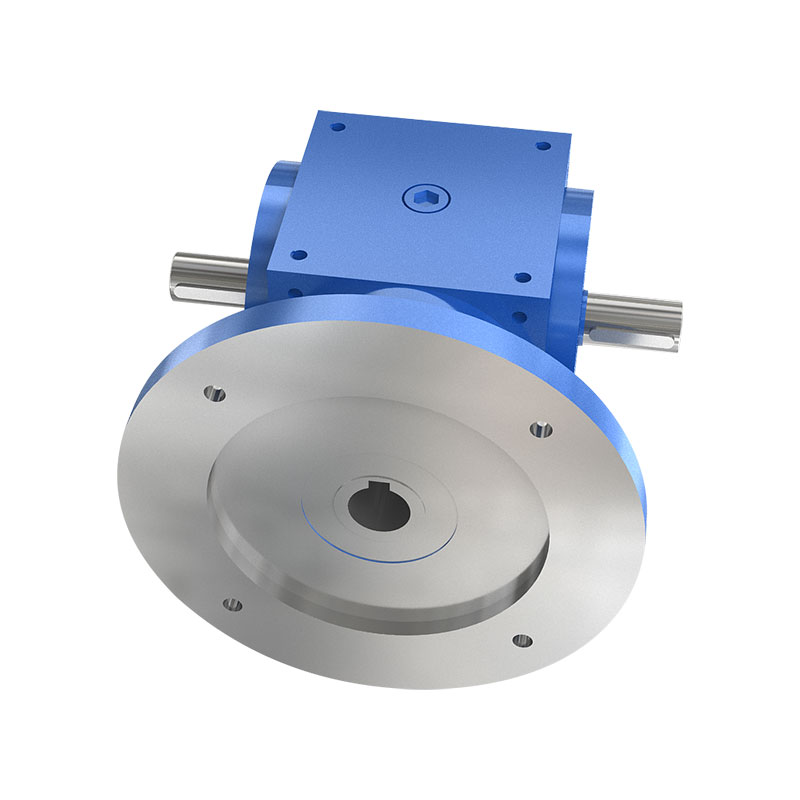

Modular Configurations: Adaptable to various PTO (Power Take-Off) systems and hydraulic integrations.

Maintenance Best Practices for Prolonging the Lifespan of T Series Spiral Bevel Gearboxes

Spiral bevel gearboxes, such as the T Series Steering Gearbox, are critical for heavy-duty applications in agriculture, construction, and material handling. Proper maintenance ensures longevity, efficiency, and reduced downtime. Below are key best practices to maximize their lifespan.

1. Regular Lubrication & Oil Management

A. Correct Lubricant Selection

Use high-quality gear oil with the right viscosity (ISO VG 220 or as per manufacturer specs).

Synthetic oils may be preferred for extreme temperatures.

Avoid mixing different lubricant types.

B. Oil Change Intervals

Replace oil every 1,000–2,000 operating hours (or per OEM guidelines).

In harsh conditions (dusty, wet, high-load environments), shorten intervals by 20–30%.

C. Oil Contamination Prevention

Check for water ingress, metal particles, or sludge (indicators of wear or seal failure).

Use magnetic drain plugs to capture ferrous debris.

Ensure breathers are clean to prevent pressure buildup.

2. Inspection & Wear Monitoring

A. Visual & Auditory Checks

Look for oil leaks (seal/gasket failures).

Listen for unusual noises (whining, grinding = misalignment or gear wear).

B. Backlash & Gear Mesh Inspection

Excessive backlash indicates gear wear or bearing failure.

Use dial indicators to measure play (follow OEM tolerances).

C. Bearing & Shaft Condition

Check for bearing play, overheating, or roughness during rotation.

Inspect shafts for bending or misalignment (causes premature wear).

3. Proper Alignment & Mounting

Misalignment causes uneven load distribution → premature failure.

Use laser alignment tools for precision.

Ensure mounting bolts are torqued correctly (prevents vibration-induced damage).

4. Seal & Gasket Maintenance

Replace worn seals immediately to prevent contamination.

Use high-temperature, chemical-resistant seals in harsh environments.

Apply sealants properly during reassembly (avoid over-tightening).

5. Load & Operational Best Practices

Avoid shock loads (sudden jerks or overloading).

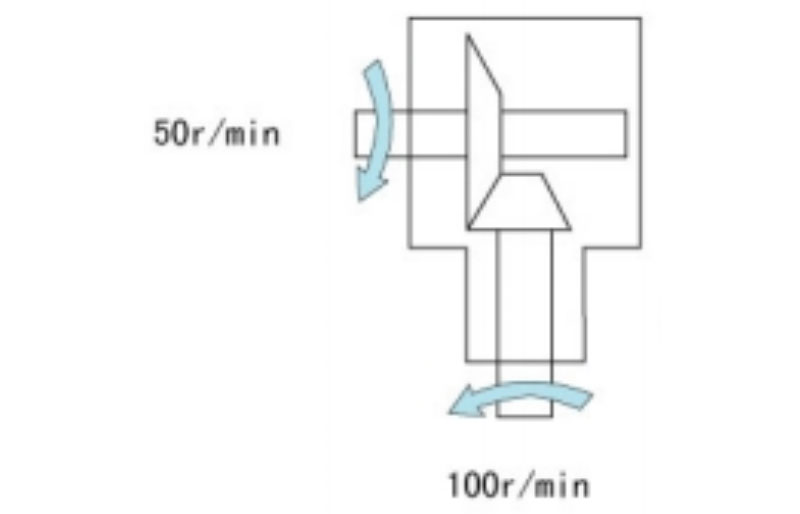

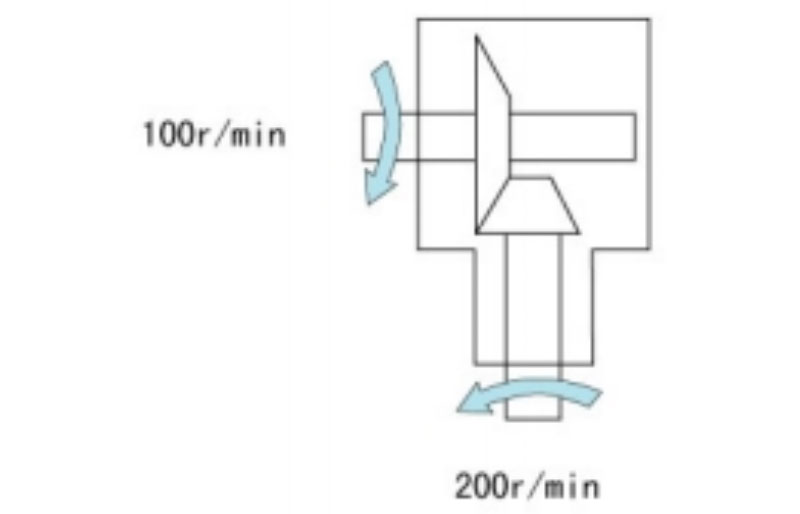

Ensure proper PTO (Power Take-Off) speed matching to prevent excessive stress.

In cold starts, allow warm-up time before full load operation.

6. Storage & Long-Term Idle Care

If unused for extended periods:

Drain old oil and refill with fresh lubricant.

Rotate shafts occasionally to prevent brinelling (bearing indentations).

Store in a dry, temperature-controlled environment.

7. When to Rebuild or Replace?

Rebuild if:

Gears show moderate pitting/spalling (but no tooth breakage).

Bearings are worn, but housings are intact.

Replace if:

Severe tooth chipping, cracking, or catastrophic failure occurs.

Housing is warped or cracked (compromises structural integrity).

English

English 中文简体

中文简体 Español

Español