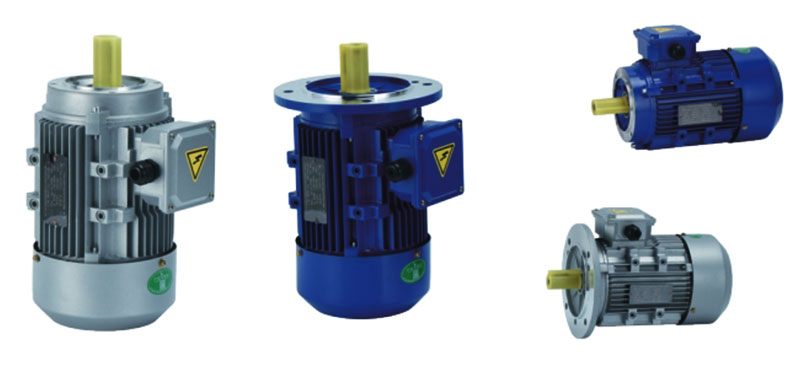

YE3 series aluminum alloy shell three-phase asynchronous motor: energy efficiency standards and energy-saving advantages analysis

With the continuous improvement of energy efficiency requirements in the global industrial field, high-efficiency and energy-saving motors have become the mainstream trend of industry development. The YE3 series three-phase asynchronous motor adopts an aluminum alloy shell design, which meets the IE3 energy efficiency standard and performs well in energy saving, heat dissipation and lightweight. As one of the core products of HENGBAI, this series of motors is widely used in industrial transmission, pumps, fans, compressors and other fields with its excellent technical performance and reliable quality, and is exported to more than 30 countries and regions around the world.

1. Comply with international energy efficiency standards and have significant energy-saving advantages

YE3 series motors strictly follow the IE3 (International Energy Efficiency Level 3) standard. Compared with traditional IE1 and IE2 motors, their losses are reduced by 15%~30%, and the comprehensive energy efficiency is significantly improved. As a member of the China Industrial Machinery Transmission Industry Association, HENGBAI's YE3 motors have passed multiple international certifications such as CE, ROHS, CQ, etc., meeting the environmental protection and energy efficiency requirements of the EU and global markets, helping customers reduce long-term operating costs.

2. Aluminum alloy housing: the perfect combination of lightweight and efficient heat dissipation

Compared with traditional cast iron motors, HENGBAI's YE3 series uses a high-strength aluminum alloy housing with the following advantages:

Lightweight: 20%~30% lighter, easy to install and maintain, especially suitable for mobile devices or space-constrained scenarios.

Excellent heat dissipation: Aluminum alloy has good thermal conductivity, effectively reduces the temperature rise of the motor, extends the life of the insulation material, and improves operational stability.

Strong corrosion resistance: Adapts to harsh environments such as humidity and dust, and is suitable for chemical, marine, food processing and other industries.

3. HENGBAI technical guarantee: core competitiveness from R&D to global service

Since its establishment in 1988, HENGBAI has always focused on the R&D and manufacturing of motors and reducers, with a professional technical team, advanced production equipment and a strict quality management system. The YE3 series motors use high-quality electromagnetic materials and precision processing technology to ensure low noise, high torque and long life. In addition, the company provides a global after-sales service network covering the United States, Germany, Southeast Asia, the Middle East and other markets to ensure customers worry-free use.

4. Wide application areas, helping green manufacturing

HENGBAI's YE3 motor has been successfully applied to:

Fluid machinery (water pumps, fans)

Material transportation (conveyor belts, mixing equipment)

Food and pharmaceuticals (hygienic environment requirements)

Environmental protection equipment (wastewater treatment, air purification) due to its high efficiency and energy-saving characteristics

English

English 中文简体

中文简体 Español

Español