How to optimize the energy efficiency and life of single-phase aluminum wire induction motors? ——HENGBAI's design points and maintenance strategies

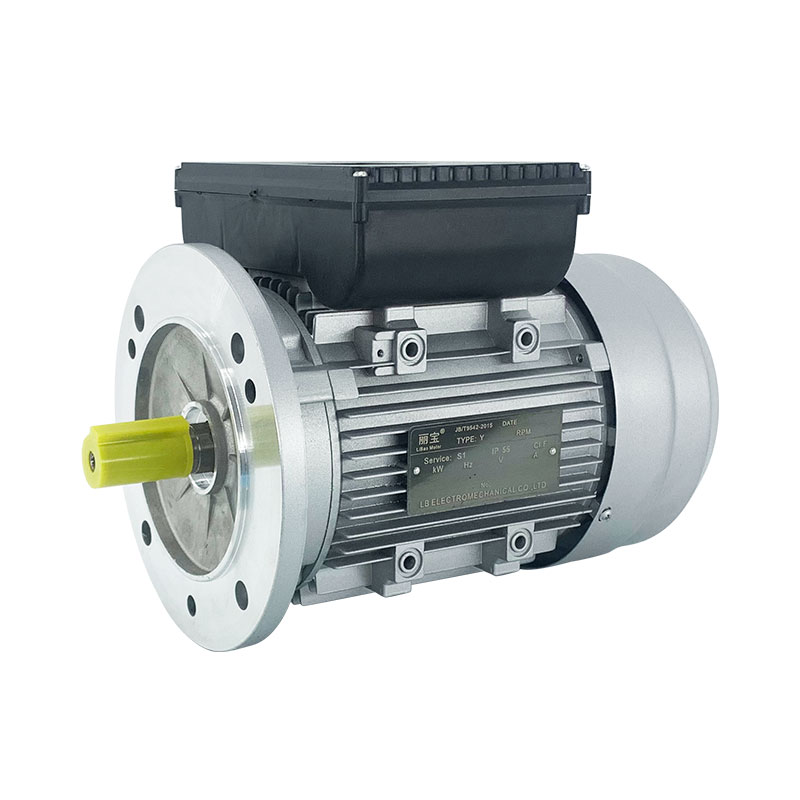

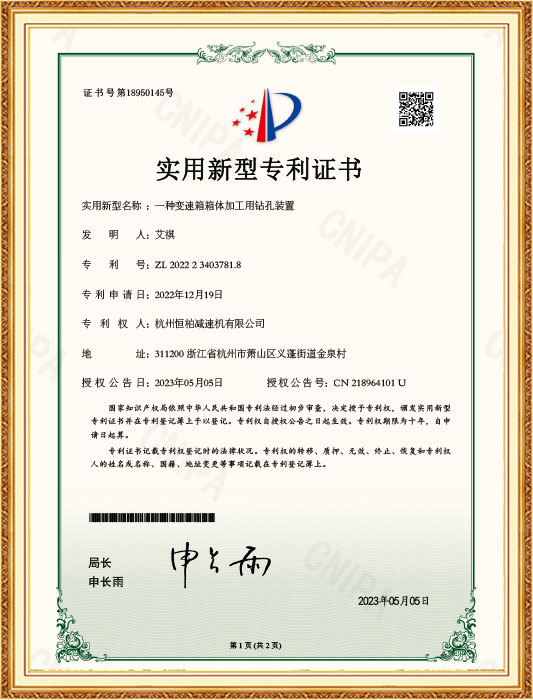

As a motor and reducer manufacturer with more than 30 years of industry experience, HENGBAI has always focused on efficient and durable transmission solutions since its establishment in 1988. With a professional technical team, advanced production equipment and a strict quality management system (ISO, CE, ROHS and other certifications), our single-phase aluminum wire induction motors are known for their high cost performance, lightweight and long life, and are exported to more than 30 countries and regions including Europe, America, the Middle East, and Southeast Asia.

The following combines HENGBAI's practical experience to analyze how to improve the energy efficiency and reliability of single-phase aluminum wire induction motors from the two aspects of design optimization and maintenance strategy:

1. Design optimization: improve energy efficiency and durability

Precision process of aluminum wire windings

Use high-purity aluminum conductors, optimize cross-sectional area and insulation coating, and balance conductivity and cost (compared with copper wire, aluminum wire is light and low in cost, but requires higher technology to ensure contact resistance stability).

HENGBAI reduces the risk of aluminum wire oxidation and enhances insulation strength through automated winding equipment and vacuum varnishing process.

Optimized heat dissipation structure

Aluminum shell motors are light but require higher heat dissipation. HENGBAI designs reinforced rib heat dissipation slots and matches them with high-quality heat dissipation fans to ensure that the temperature rise is controlled within the IEC standard range.

High-efficiency magnetic circuit design

Optimize the lamination process of stator and rotor punching, use low-loss silicon steel sheets, reduce eddy current losses, and improve energy efficiency (in line with IE2 and above energy efficiency standards).

Bearing and mechanical protection

Select IP54/IP55 protection level design, dust and moisture proof; configure long-term lubricated bearings (such as NSK/SKF brands) to adapt to harsh working conditions.

2. Maintenance strategy: the key to extending motor life

Regular inspection and cleaning

Clean the dust and heat dissipation holes of the motor housing to avoid blockage and overheating (HENGBAI provides a visual maintenance guide to guide user operations).

Voltage and load monitoring

Single-phase motors are sensitive to voltage fluctuations. It is recommended to use them with a voltage stabilizer to avoid long-term overload operation (our motors are equipped with overload protection devices as standard).

Lubrication and bearing maintenance

Replenish grease every 3000-5000 hours of operation (HENGBAI motors use maintenance-free bearing design, and some models can be extended to 10,000 hours).

Preventive testing

Use a vibration analyzer or infrared thermometer for regular testing to detect problems such as winding aging and bearing wear at an early stage (HENGBAI after-sales team provides remote diagnosis support).

3. HENGBAI's value-added services

Customized design: adjust power, speed, and protection level according to customer needs (such as anti-corrosion treatment for tropical climates).

Global after-sales network: Service points are set up in Germany, the United States, Southeast Asia and other places to provide rapid technical response.

Quality commitment: All motors are tested at full load for 72 hours before leaving the factory to ensure reliability.

English

English 中文简体

中文简体 Español

Español