Selection Guide and Load Matching Strategy of PL PF Planetary Reducer in Industrial Automation Scenarios

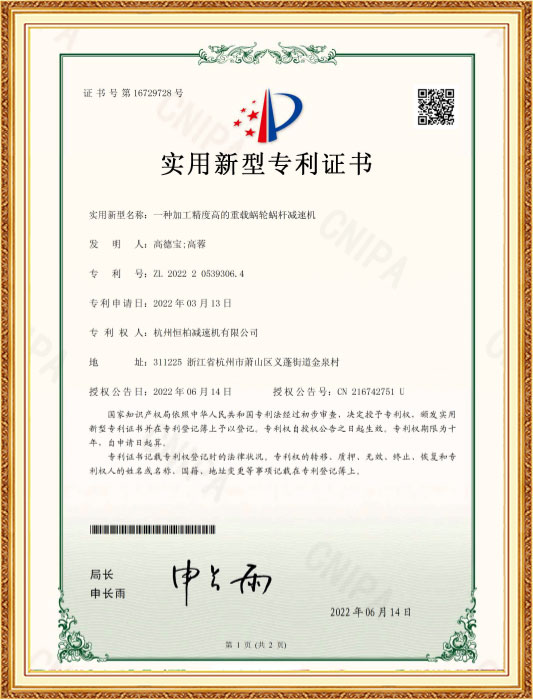

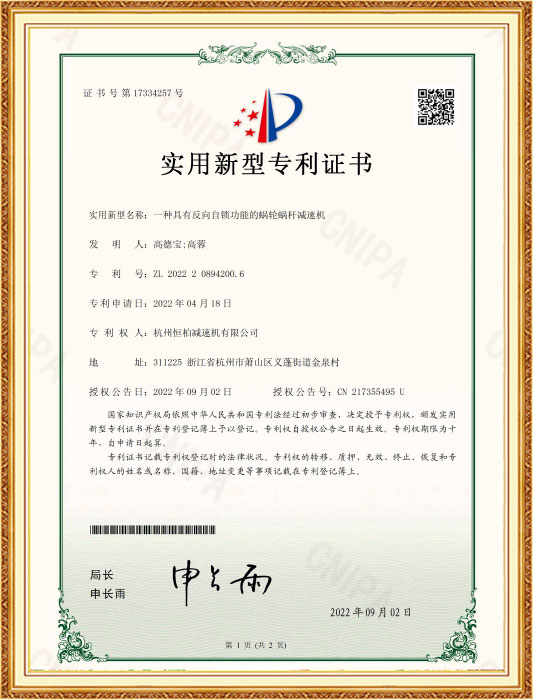

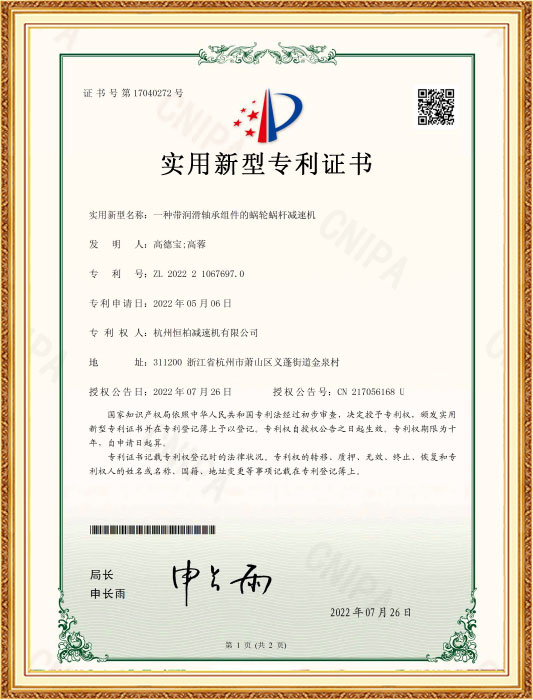

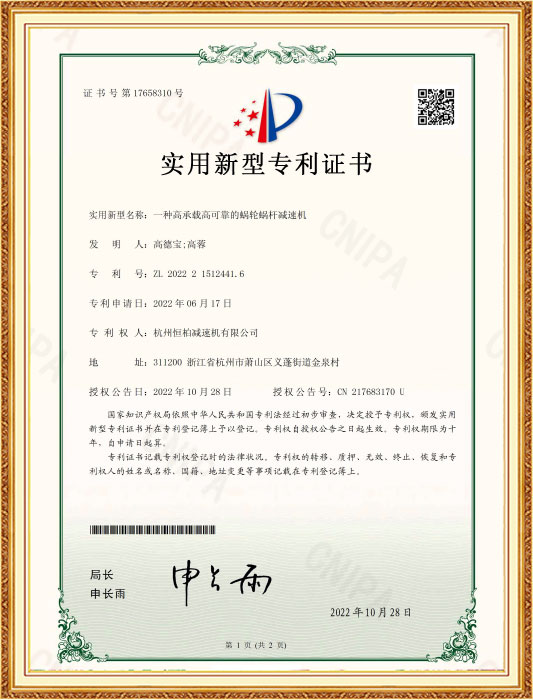

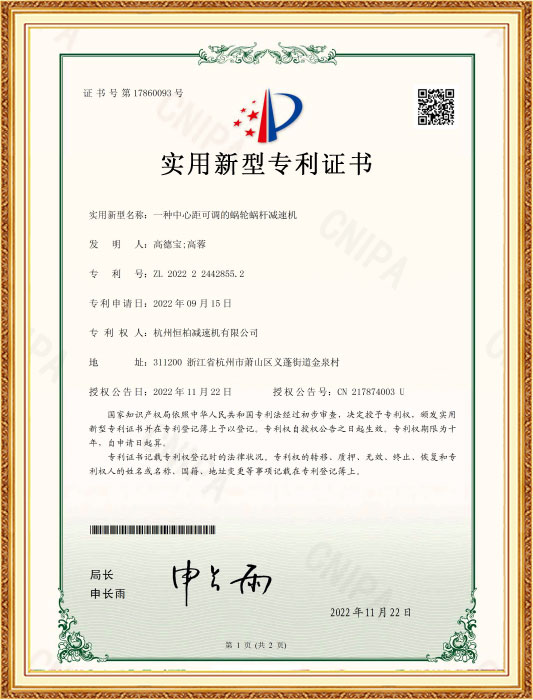

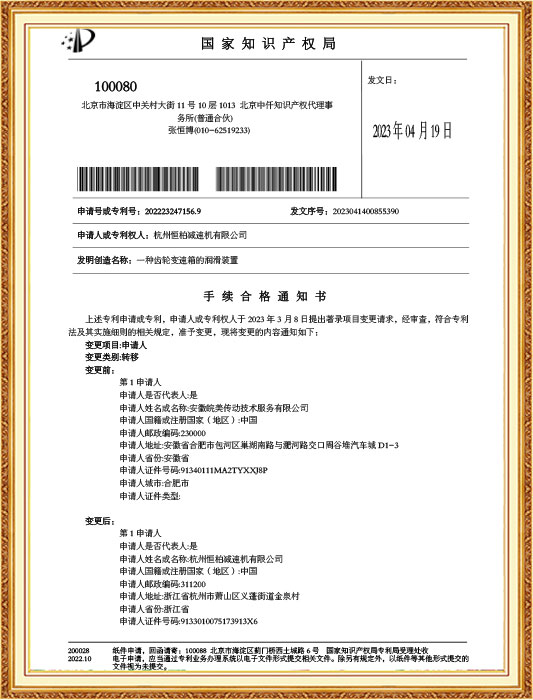

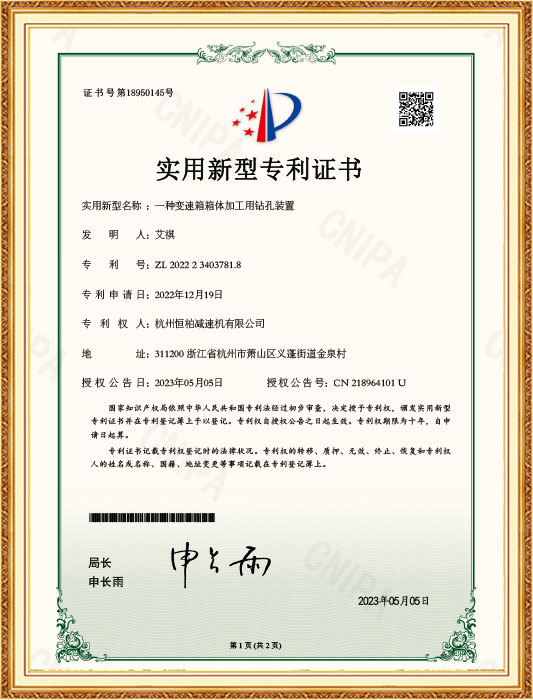

Founded in 1988, HENGBAI is a company specializing in the research and development and manufacturing of gearboxes, reducers, and motors. It is also a member of the China Industrial Machinery Transmission Industry Association. The company has a number of honorary qualifications and credit ratings, and has obtained authoritative certifications such as quality management system certification, ROHS, CE, CQ, IP, and AAA.

HENGBAI has a professional technical team, a scientific management system, strong economic strength, advanced processing equipment, and a complete after-sales service system. Its products are sold well at home and abroad, and are exported to more than 30 countries and regions including the United States, Germany, the United Kingdom, France, Dubai, Russia, Mexico, Colombia, Peru, India, Thailand, and Vietnam.

Selection Guide for PL PF Series Precision Planetary Reducers

In the field of industrial automation, the selection of planetary reducers directly affects the operating efficiency, accuracy, and life of the equipment. HENGBAI's PL PF series precision planetary reducers are widely used in scenarios such as robotic arms, CNC machine tools, automated production lines, and logistics sorting systems due to their advantages of high precision, high rigidity, and low backlash.

1. Key selection parameters

Reduction ratio (Ratio): According to the matching of motor speed and load requirements, the common reduction ratio is 3~100.

Rated torque (Rated Torque): Ensure that the reducer can withstand the maximum torque of the load.

Backlash (Backlash): High-precision applications (such as robots) require low backlash models (such as ≤3arcmin).

Input/output interface: Match servo motor or stepper motor flange (such as IEC, NEMA standards).

Protection level (IP Rating): Industrial environment requires IP65 or above, dustproof and waterproof.

2. Load matching strategy

Dynamic load (such as robotic arm): Peak torque + inertia matching needs to be calculated to avoid overload.

Continuous operation (such as conveyor line): Pay attention to thermal power to prevent overheating during long-term operation.

Impact load (such as stamping equipment): choose models with high rigidity gears + reinforced bearings.

3. Advantages of HENGBAI PL PF series

High precision (≤1arcmin optional), suitable for robots and semiconductor equipment.

Modular design, suitable for mainstream servo motor brands (such as Panasonic, Yaskawa, Siemens).

Long-life lubrication, maintenance-free design, reduce downtime.

Global certification (CE, ROHS), in line with international standards, worry-free export.

English

English 中文简体

中文简体 Español

Español