Maintenance and Lubrication Guide: Practical Methods to Extend the Service Life of SWL Worm Gear Screw Jacks

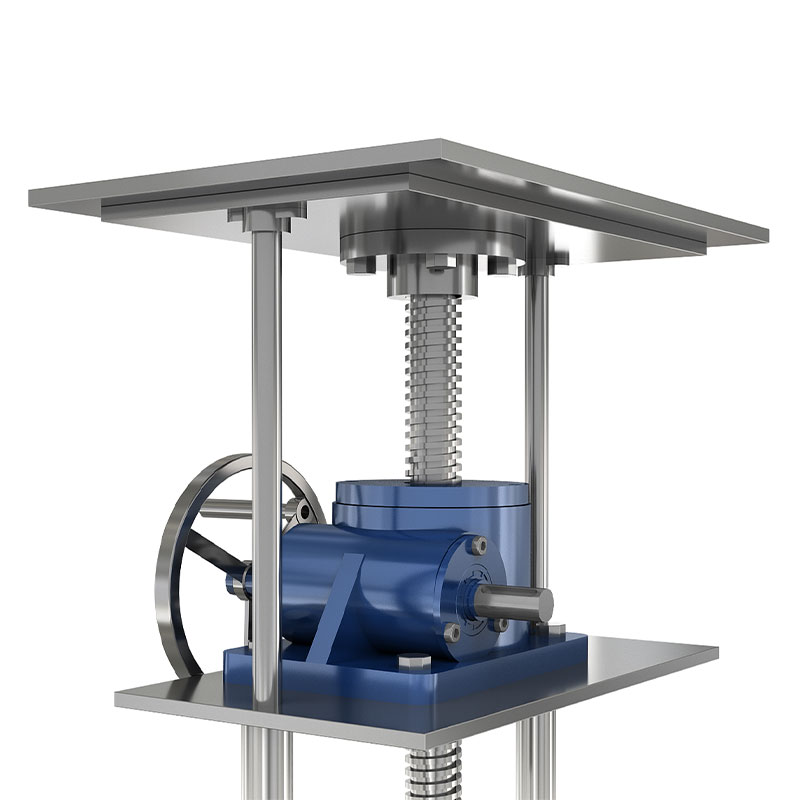

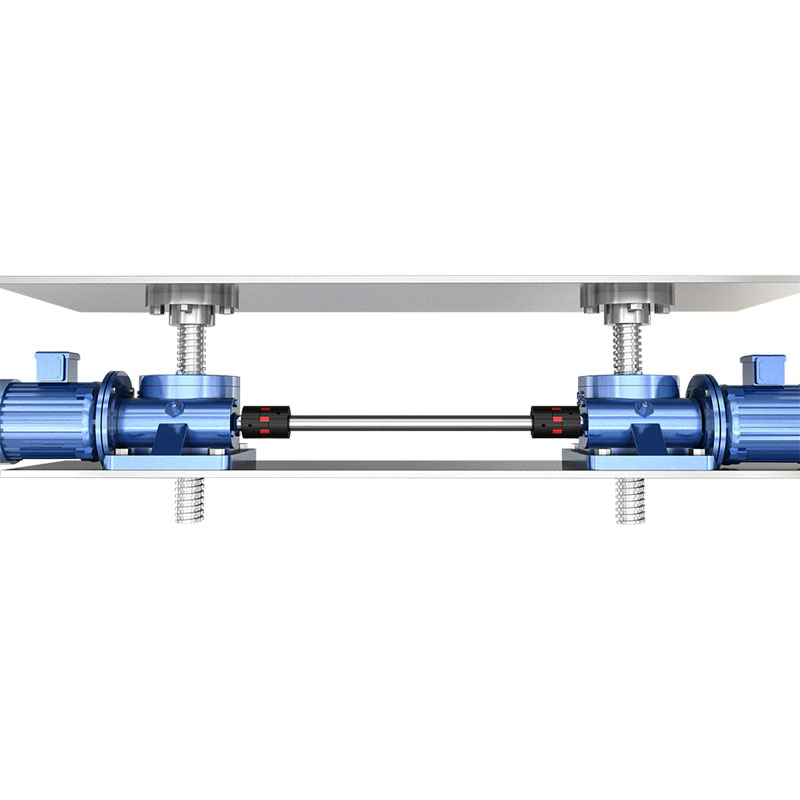

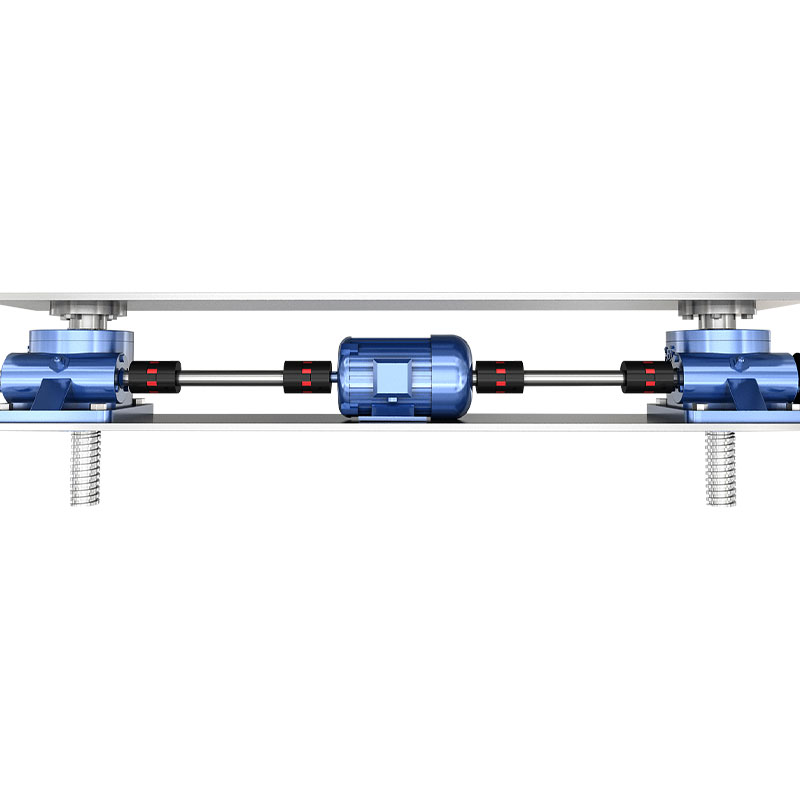

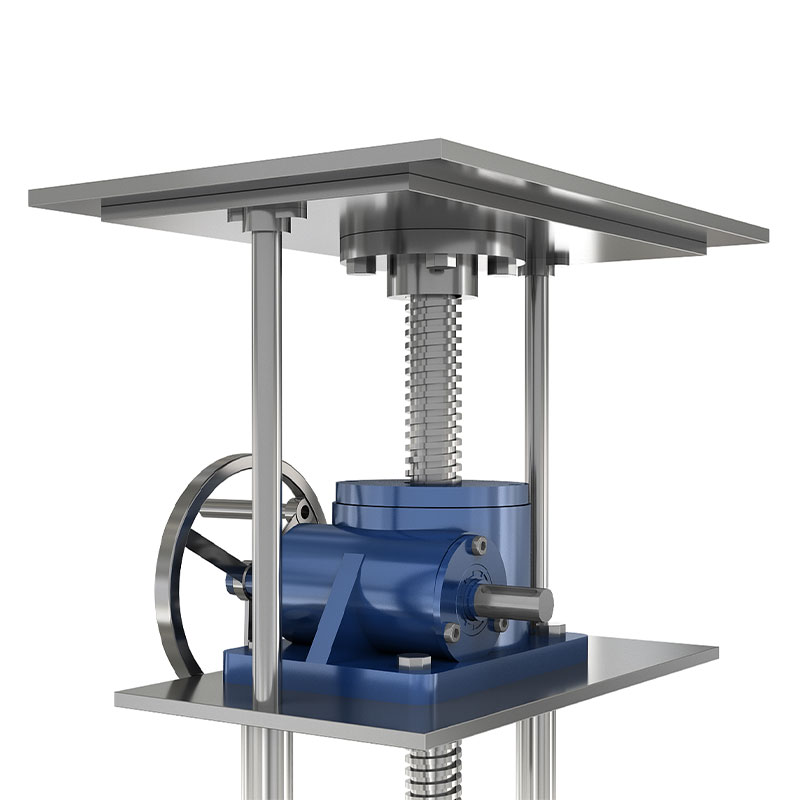

SWL (Safe Working Load) worm gear screw jacks are widely used in industrial lifting, positioning and other scenarios due to their high load capacity, self-locking and stability. However, wear, insufficient lubrication or improper operation during long-term use can lead to performance degradation.

Daily Maintenance Inspection

Appearance and Structural Inspection

Check whether the housing has cracks, deformation or corrosion.

Confirm that there are no scratches, rust or thread wear on the surface of the screw (screw shaft).

Check whether the meshing parts of the worm gear are loose or abnormally worn.

Load and Operation Test

No-load operation test: manually turn the handle or motor to observe whether it is smooth and without jamming.

Load test: operate within the rated SWL range and monitor for abnormal noise or vibration.

Fasteners and sealing

Make sure all bolts and nuts are tightened to prevent looseness and structural failure.

Check whether the seals (such as dust rings) are aged to prevent contaminants from entering the interior.

Lubrication management

Lubricant selection

Worm gear part: Use high-viscosity industrial gear oil (such as ISO VG 220) or lithium-based grease, which must have extreme pressure (EP) performance.

Screw (helical shaft): Apply high-temperature resistant grease (such as molybdenum disulfide grease) to reduce friction and wear.

Lubrication cycle

Normal working conditions: Relubricate once every 3-6 months, or check after every 500 operations.

Harsh environment (dusty, high temperature, high humidity): shorten to 1-3 months, and increase sealing protection.

Lubrication operation steps

Clean the oil filling port and surrounding dirt to avoid impurities.

Use a grease gun or apply manually to ensure that the lubricant covers the worm gear tooth surface and screw thread.

Excessive lubrication needs to be removed to prevent oil accumulation from absorbing dust.

Common faults and solutions

1. Jamming or unsmooth operation

Possible causes:

Insufficient lubrication or lubricant contamination

Foreign matter (such as dust, metal debris) on the screw thread or worm gear tooth surface

Bearing damage or deformation of internal parts

Solution:

Clean the screw and worm gear parts and remove impurities

Refill with appropriate lubricant (such as high-viscosity gear oil or molybdenum disulfide grease)

Check whether the bearing is damaged and replace it if necessary

2. Abnormal noise (metal friction sound, knocking sound)

Possible causes:

Poor meshing of worm and gear, wear on tooth surface

Damage to bearing or sleeve

Bending of screw or partial damage to thread

Solution:

Check the meshing of worm and gear, adjust the clearance or replace the worn parts

Replace the damaged bearing or sleeve

If the screw is deformed, replace it with a new screw

3. Load capacity decreases (lifting failure)

Possible reasons:

Overload causes fatigue of the screw or worm gear

Poor lubrication, increased friction

Thread wear, reduced transmission efficiency

Solution:

Ensure use within the rated SWL (safe working load) range

Check lubrication and replace with a higher performance lubricant if necessary

If the thread is severely worn, the screw or worm gear needs to be replaced

4. Self-locking function fails (load slides)

Possible reasons:

The clearance between the worm gear and the worm is too large, and self-locking is impossible

Reverse driving force is too large (such as lateral force impact)

Lubricant is too thin or the lubrication method is wrong

Solution:

Adjust the meshing clearance of the worm gear to ensure self-locking

Avoid lateral force to ensure vertical lifting

Replace with a suitable lubricant (such as high-viscosity grease)

5. Oil leakage or lubricant contamination

Possible causes:

Aging or damage of seals (such as O-rings, dust covers)

Overfilling of lubricants, resulting in overflow

Dust and moisture intrusion in the working environment

Solution:

Replace damaged seals

Clean up excess lubricants and add them according to the standard amount

Improve the working environment or add protective covers

6. Handle rotation is difficult (manual type)

Possible causes:

Insufficient lubrication, high friction resistance

Rust on internal parts (especially in humid environments)

Excessive load or mechanical jamming

Solution:

Check lubrication, replenish or replace lubricants

If rust is severe, disassemble, clean and treat with rust prevention

Confirm whether the load exceeds the limit and avoid forced operation

Long-term storage recommendations

Clean the equipment and apply anti-rust oil, and wrap the dust cover.

Store in a dry environment to prevent the screw from directly contacting the ground.

Manually rotate the screw 1-2 times every 6 months to prevent the bearing from rusting.

Safety operation reminder

Overloading is strictly prohibited (SWL is the safety upper limit), otherwise it may cause thread collapse or structural deformation.

Train operators regularly to ensure they are familiar with manual/electric operation specifications.

English

English 中文简体

中文简体 Español

Español