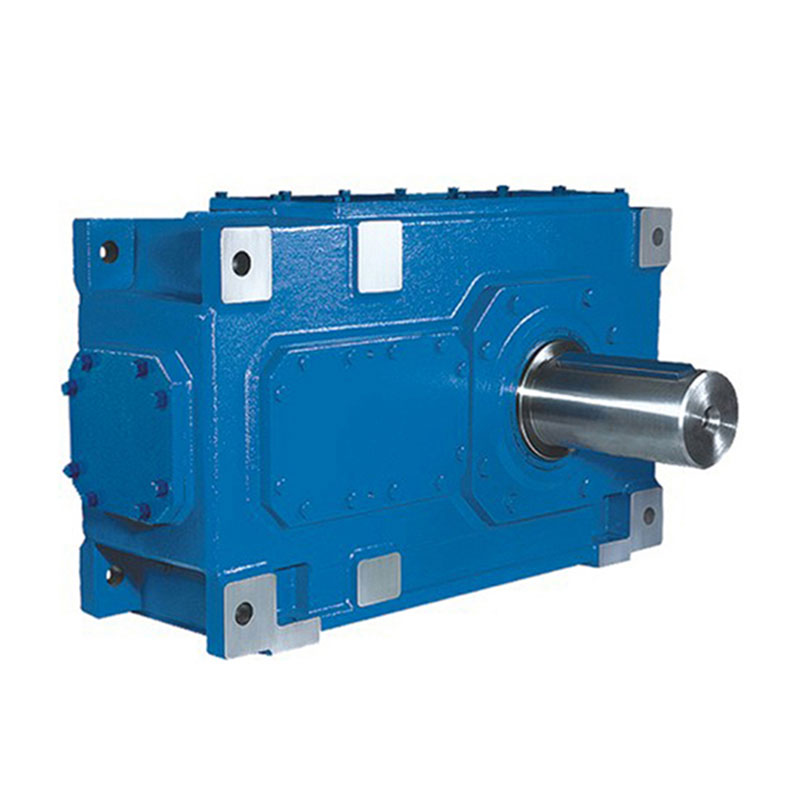

Application scenarios and performance optimization of H B Series gear units in heavy industry

As the core transmission component of heavy industrial equipment, the reliability and efficiency of industrial gearboxes directly affect the stability and energy consumption of the production line. With its high torque density, modular design and long life, H B Series gear units are widely used in heavy industries such as mining, metallurgy, cement, and port lifting. The following is an analysis of its typical application scenarios and performance optimization directions.

1. Core application scenarios

Mining and metallurgy: In equipment such as ball mills and crushers, H B Series gearboxes need to withstand high-frequency impact loads. It uses high-strength alloy steel gears and heavy-duty bearings, combined with impact-resistant housing design to ensure stability under high-vibration conditions such as ore crushing. For example, after an iron ore concentrator adopted the HB series, the gearbox life was extended by 30%, and the maintenance cycle was increased from 3 months to 6 months.

Cement production: Rotary kilns and roller presses require low-speed and high-torque transmission, and the environment is dusty. H B Series reduces dust intrusion through a sealed lubrication system and helical gear transmission, and the transmission efficiency reaches more than 96%. After the transformation of a cement group, a single production line saves more than 150,000 kWh of electricity per year.

Port hoisting: The lifting mechanism of the gantry crane needs to be precisely controlled. The HB Series is equipped with a variable frequency motor to achieve smooth start and stop. The low backlash design of the gearbox (≤5 arc minutes) ensures positioning accuracy and reduces cable wear.

2. Key technologies for performance optimization

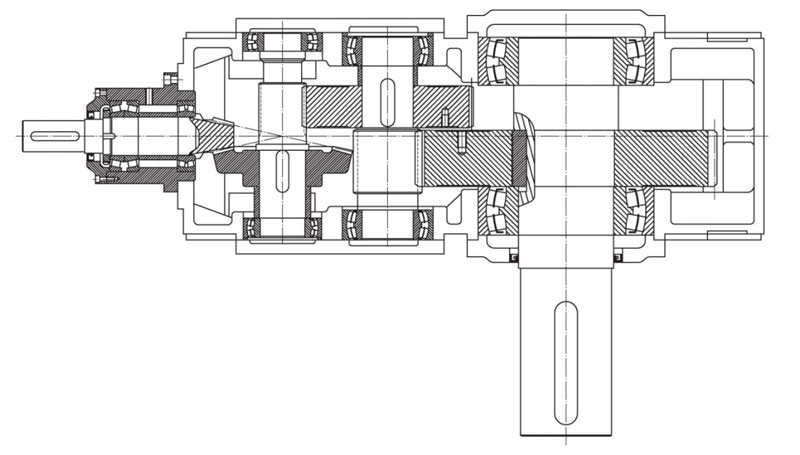

Load adaptation: Match different load curves through modular combinations (such as parallel gear stages or planetary reduction stages) to avoid energy waste of "big horses pulling small carts".

Energy efficiency improvement: The use of spiral gears + grinding technology reduces noise (≤75dB) and friction loss; some models integrate an oil cooling system to control the temperature rise within 40°C during continuous operation.

Intelligent maintenance: Built-in vibration and temperature sensors, warning of potential faults (such as tooth surface spalling) through the IoT platform, reducing unplanned downtime.

3. Industry challenges and responses

Heavy industrial environments often face extreme temperatures, dust and corrosion problems. The optimization solutions for the H B Series include:

Seal improvement: multi-layer labyrinth seal + lithium-based grease, suitable for high-humidity port environments.

Material upgrade: carbonitriding treatment on the gear surface improves wear resistance and increases service life by 50% in metallurgical high-temperature scenarios.

English

English 中文简体

中文简体 Español

Español