What Makes FCL Flexible Couplings a Game-Changer in Mechanical Systems?

In the world of mechanical power transmission, the role of couplings is paramount. They link two shafts together, allowing them to transmit motion and torque while compensating for misalignment between the shafts. Among the various types of couplings available, FCL (Flexible Coupling) stands out for its durability, versatility, and efficiency in demanding applications.

Understanding FCL Flexible Couplings

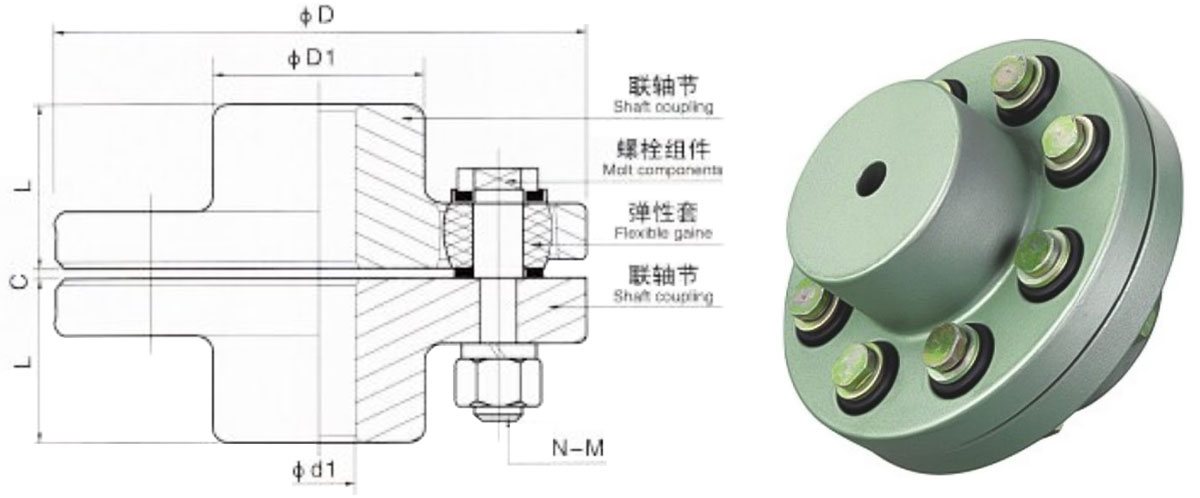

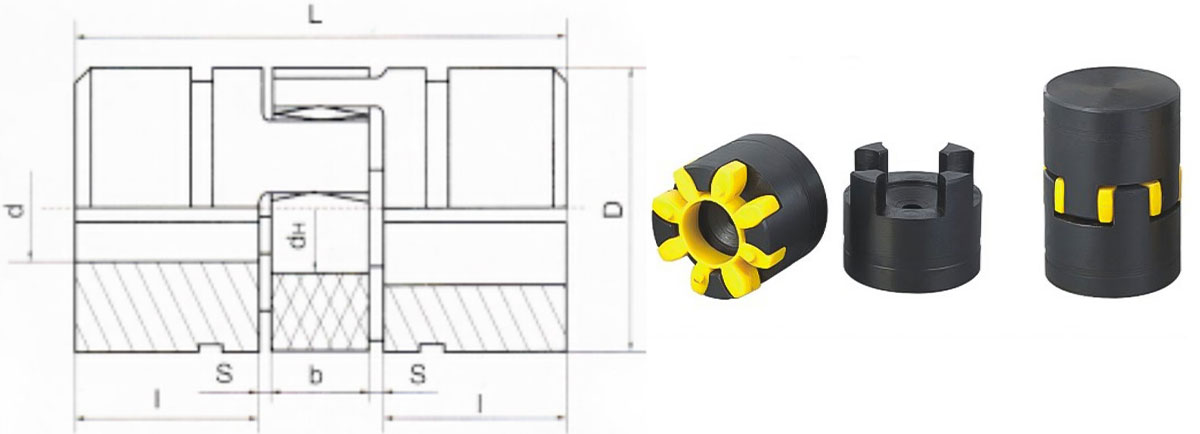

FCL Flexible Couplings are mechanical devices designed to connect two shafts while accommodating for misalignments in their position or angle. These couplings are generally made from high-quality materials such as rubber, steel, or composites that allow them to absorb shock and vibration, which are common in industrial settings. As industries evolve and machinery grows more complex, FCL couplings are increasingly favored for their ability to enhance system performance and longevity.

Unlike rigid couplings, which are designed for systems with perfectly aligned shafts, FCL couplings provide the flexibility needed to compensate for angular, parallel, or axial misalignment. This flexibility minimizes wear and tear on both the motor and the driven equipment, leading to less maintenance and longer operational life.

The Role of FCL Flexible Couplings in Reducing Maintenance Costs

One of the key benefits of using FCL Flexible Couplings is the significant reduction in maintenance costs. In many mechanical systems, misalignment between shafts can lead to excessive wear, overheating, and even equipment failure. However, FCL couplings can absorb these misalignments, thus protecting both the motor and the driven machine from damage.

Over time, this protection results in lower maintenance costs because parts last longer and systems require fewer repairs. Industries such as manufacturing, automotive, and robotics, where precision and continuous operation are vital, greatly benefit from these couplings.

Applications of FCL Flexible Couplings

FCL Flexible Couplings find applications across a wide range of industries. They are commonly used in mechanical systems that require precise torque transmission but may experience some form of misalignment during operation.

Automated Equipment: Robots and automated production lines often rely on flexible couplings to ensure the integrity of their movements, even when slight misalignments occur.

Pumps and Compressors: These machines often experience variations in load and pressure, requiring the use of flexible couplings to maintain smooth, consistent operation.

Wind Turbines: In renewable energy systems, flexible couplings help manage the rotational forces generated by turbine blades, allowing for better efficiency and protection against mechanical failure.

Marine Applications: Boats and ships rely on flexible couplings to connect engines to propellers, compensating for slight misalignments due to hull distortion or other factors.

With such diverse applications, the importance of FCL Flexible Couplings cannot be overstated, as they help ensure the stability and reliability of machinery across various sectors.

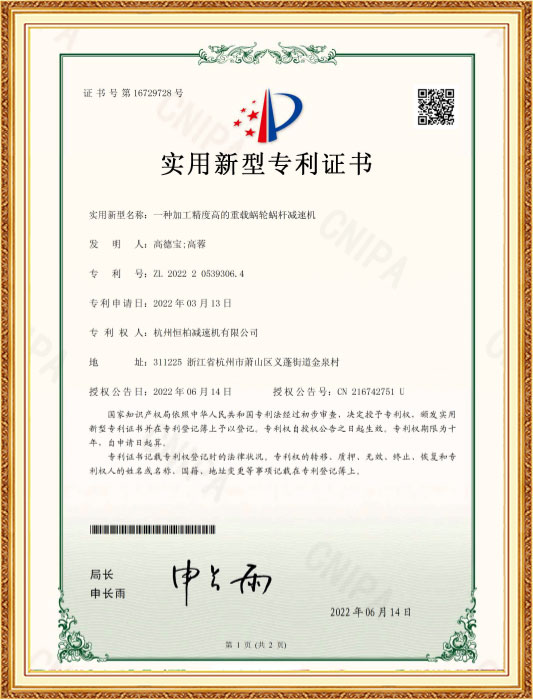

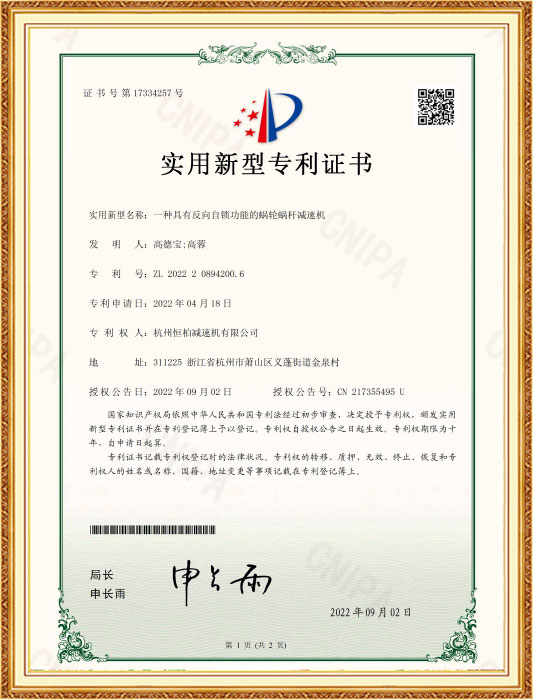

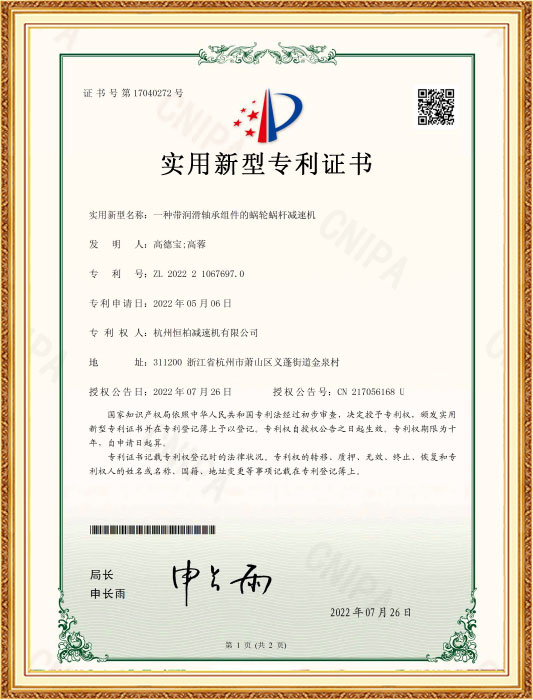

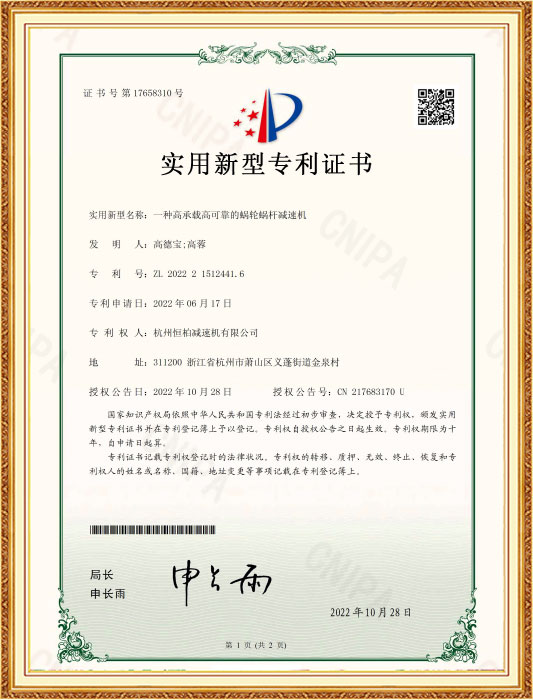

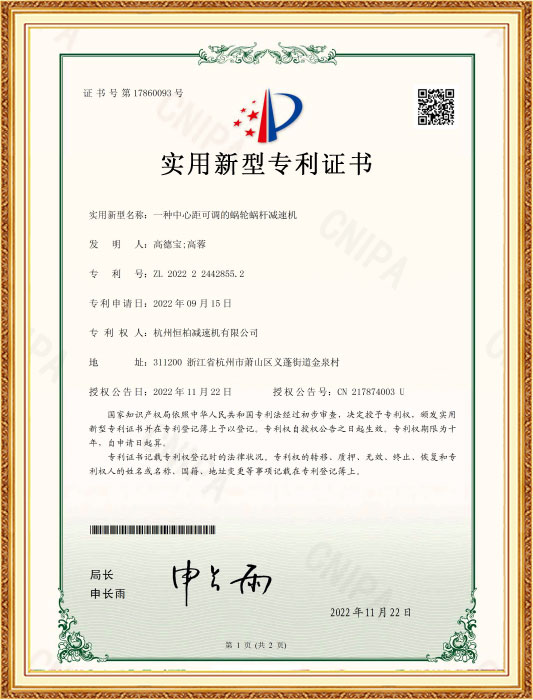

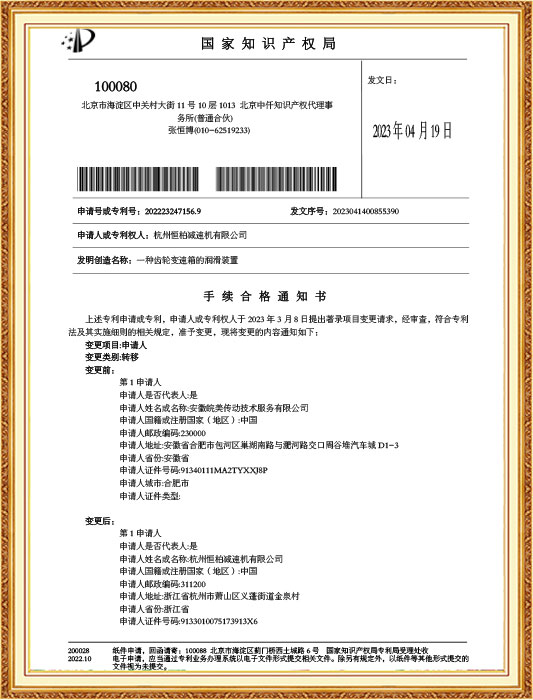

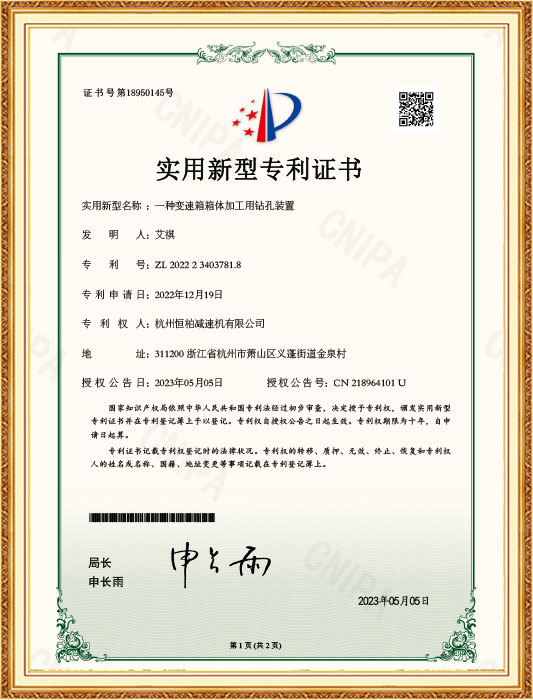

As a leading player in the gear and transmission industry, Hangzhou Hengbai Reducer Co., Ltd. has been at the forefront of producing high-quality gearboxes, reducers, motors, and couplings, including FCL Flexible Couplings. The company has garnered a reputation for its commitment to technological innovation, advanced manufacturing processes, and exceptional customer service.

Hangzhou Hengbai Reducer Co., Ltd. plays a pivotal role in the development and distribution of FCL Flexible Couplings, offering products that meet international quality standards. Their products are trusted by industries around the world, including those in the United States, Germany, the United Kingdom, and more than 30 countries across Asia, Africa, and Latin America. This global reach highlights the company's ability to deliver reliable, high-performance solutions to a wide range of mechanical systems.

By investing in research and development, Hangzhou Hengbai Reducer ensures that its FCL Flexible Couplings incorporate the latest advancements in materials and manufacturing technologies. This focus on innovation is what keeps them ahead of the competition, helping industries around the world optimize their operations.

For businesses seeking to enhance the efficiency and reliability of their mechanical systems, FCL Flexible Couplings offer a comprehensive solution. From reducing maintenance costs to improving the longevity of machinery, the advantages are clear.The continuous improvements in materials science and design ensure that these couplings can meet the evolving demands of modern industries.

English

English 中文简体

中文简体 Español

Español