What are the lubrication methods and lubricant selection requirements for FC (WP) series worm gear reducers?

1. Lubrication methods for FC (WP) series worm gear speed reducers

The notable feature of worm gear transmission is that the relative sliding speed is large when the tooth surfaces are meshing, which is easy to generate friction heat. If the lubrication is insufficient, it will lead to increased wear of the tooth surfaces, excessive temperature rise, and even bonding failure. Therefore, the lubrication of the FC (WP) series reducers needs to take into account the cooling, friction reduction and cleaning functions. Common lubrication methods include the following two categories:

(I) Oil bath lubrication (oil immersion lubrication)

Applicable scenarios: Applicable to low-speed conditions with a worm circumferential speed of v≤4-5m/s, or the normal operation scenarios of small and medium-sized reducers.

Operation principle: Immerse part of the worm wheel or worm in the lubricating oil, and use the gear rotation to bring up the oil to achieve lubrication of the tooth surface and bearings. Generally, when the worm-down reducer (the worm is located below the worm wheel) is lubricated with oil, the oil level needs to submerge the worm tooth surface, or at least reach the center height of the worm shaft; if it is a worm-up type, it needs to submerge about 1/3 of the worm wheel tooth width.

Advantages: simple structure, low maintenance cost, reusable oil and certain cooling effect.

Note: The oil level needs to be checked regularly to avoid insufficient lubrication due to oil leakage or evaporation; when running at high speed, the oil temperature may rise due to excessive oil stirring loss, and it needs to be used with a cooling device.

(II) Pressure circulation lubrication (forced lubrication)

Applicable scenarios: When the worm circumferential speed v>5m/s or the equipment power is large and the operating load is heavy, a pressure circulation lubrication system is required.

Operating principle: The lubricating oil is pumped out of the oil tank through the oil pump and transported to the worm gear meshing area and bearing part through the pipeline to achieve forced lubrication. After lubrication, the oil returns to the oil tank and is recycled after cooling and filtration.

Advantages: Stable lubrication effect, effective control of oil temperature, adaptable to high load and high speed conditions; the filter device can remove impurities in the oil and reduce abrasive wear.

Components: Usually includes oil pump, oil filter, cooler, oil pipe, nozzle and oil temperature monitoring device, etc. The system is relatively complex and requires regular maintenance of the oil pump and pipeline.

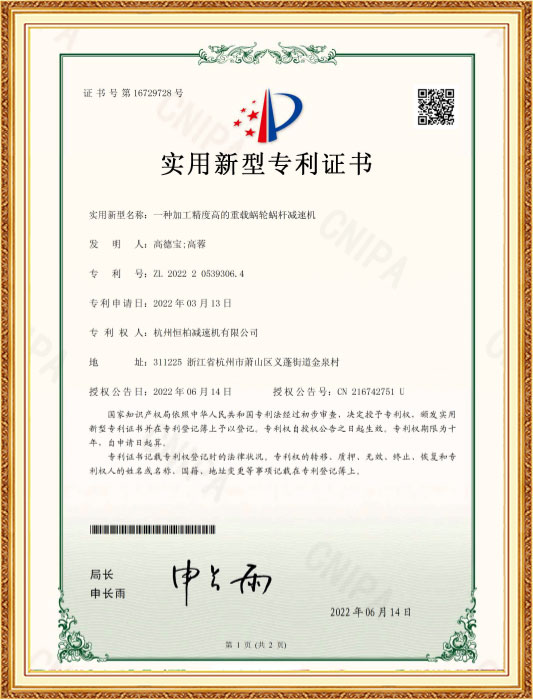

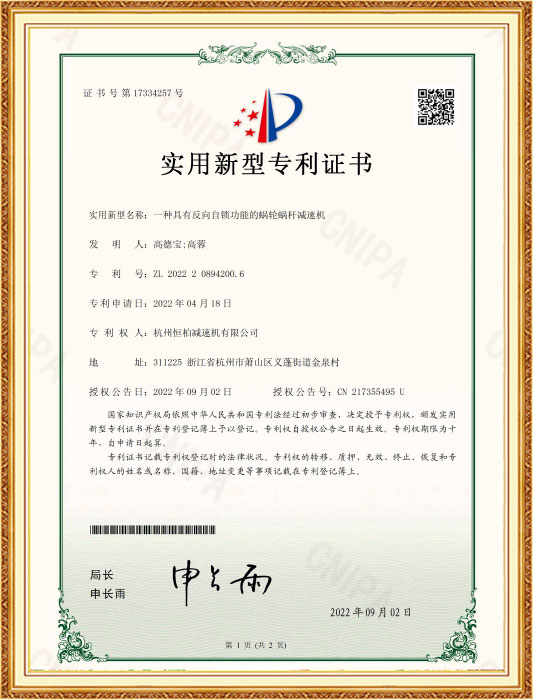

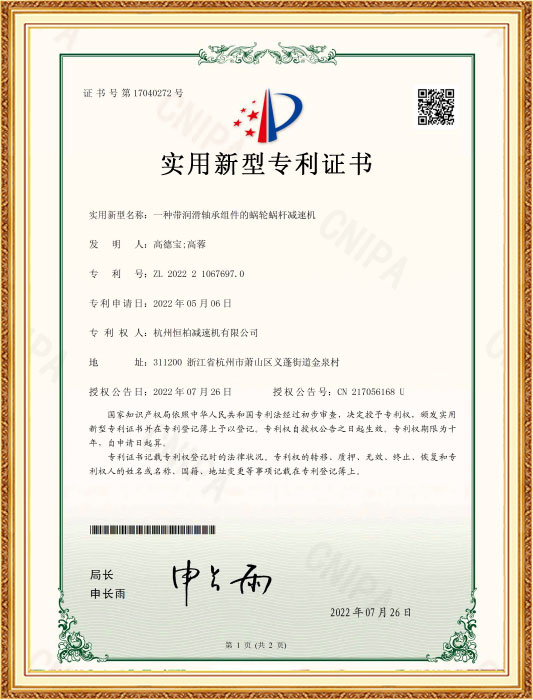

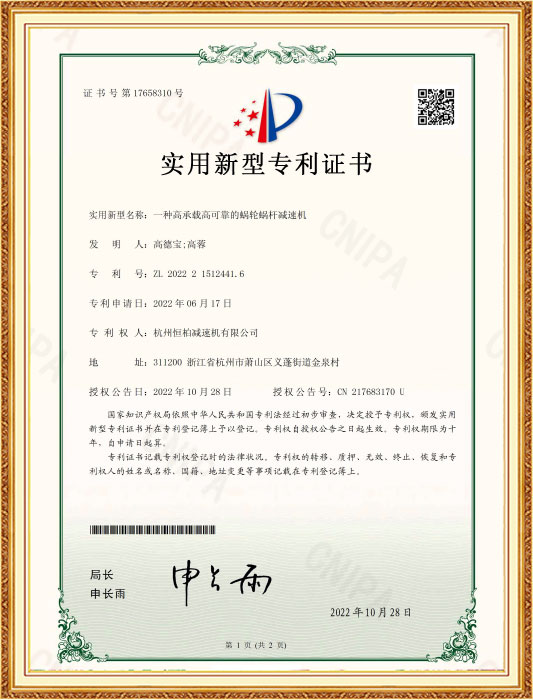

Technical support: As a manufacturer with independent testing laboratories and advanced equipment, Hangzhou Hengbai Reducer Co., Ltd will recommend suitable lubrication methods according to customer working conditions in the design of FC (WP) series reducers. For example, for high-load equipment in industries such as plastics and metallurgy, pressure circulation lubrication may be preferred, and the heat dissipation efficiency and oil cleanliness of the lubrication system may be verified by testing equipment to ensure the reliability of the product in actual applications.

2. Principles and specific requirements for lubricant selection

The performance of lubricants directly affects the transmission efficiency, wear degree and service life of wp worm gear reducers. The selection of lubricating oil for FC (WP) series reducers needs to consider the following factors:

(I) Base oil type

Mineral oil

Applicable scenarios: Conventional load, medium speed conditions, such as conveying equipment in light industry, food and beverage industry.

Advantages: Low cost, sufficient supply, stable lubrication performance.

Typical brand: L - CKC medium load industrial gear oil (such as No. 46, No. 68), viscosity grade needs to be selected according to oil temperature and load.

Synthetic oil

Applicable scenarios: High temperature, high load or long-cycle operation conditions, such as heavy equipment in mining and chemical industries.

Advantages: Strong antioxidant properties, good viscosity-temperature performance, long service life, can work in a wide temperature range of -30℃ to 150℃.

Typical types: Poly α-olefin (PAO) synthetic oil, ester synthetic oil, viscosity grade can be selected from ISO VG 100 - 460.

Process matching: The foundry of Hangzhou Hengbai Reducer Co., Ltd. can produce high-precision worm gears (made of tin bronze), and compatibility with lubricants is one of the research and development focuses. For example, when tin bronze worm gears are matched with mineral oil, corrosion caused by active sulfur additives must be avoided; the high stability of synthetic oil is more suitable for high-load worm gear structures, especially in the high-temperature environment of the metallurgical industry.

(II) Additive formulation

Extreme pressure anti-wear agent: The contact stress is high when the worm gear is meshing, and extreme pressure agents such as sulfur, phosphorus, and chlorine need to be added to form a boundary lubrication film to prevent bonding. For example, sulfur-phosphorus extreme pressure agents are suitable for steel-copper friction pairs, but the sulfur content needs to be controlled to prevent copper corrosion.

Antioxidants: Delay oil aging and extend oil change cycles, especially for circulating lubrication systems.

Antifoaming agents and rust inhibitors: Reduce the foam generated by oil stirring and prevent metal parts from rusting.

Selection taboos: Avoid using lubricants containing heavy metal additives such as lead and zinc to prevent chemical reactions with the tin bronze material of the worm gear, which will increase wear.

(III) Selection of viscosity grade

Viscosity is the core indicator of lubricating oil, which needs to be determined according to the worm speed, load and working temperature:

Low speed and heavy load (such as v<2m/s): Select high viscosity oil (such as ISO VG 220-680) to form a thick oil film to resist the load.

High speed and light load (such as v>5m/s): Select low viscosity oil (such as ISO VG 68-150) to reduce oil stirring loss and temperature rise.

Ambient temperature influence: Low freezing point lubricating oil (such as synthetic oil or mineral oil with pour point depressant) should be selected in low temperature environment (such as northern winter); high temperature environment needs to increase viscosity grade or use high temperature resistant synthetic oil.

3. Key points of lubrication management and maintenance

Oil level and oil temperature monitoring: Check the oil level regularly to ensure that the oil submerges the meshing area; when the oil temperature exceeds 80℃, the cause should be checked (such as insufficient lubrication, excessive load or cooling failure), and the machine should be shut down for cooling if necessary.

Oil replacement cycle: Mineral oil is usually replaced every 6-12 months, and synthetic oil can be extended to 2-3 years, but the actual performance needs to be judged through oil testing (such as viscosity, acid value, and impurity content).

Cleanliness control: After the first 500 hours of operation of new equipment, the lubricating oil needs to be replaced and the oil tank needs to be cleaned. During subsequent maintenance, impurities such as moisture and dust should be prevented from entering the lubrication system.

Special requirements during the running-in period: It is recommended to use low-viscosity lubricating oil (such as ISO VG 100) during the running-in period of new reducers to promote tooth surface running-in. After the running-in period, replace it with normal viscosity oil.

English

English 中文简体

中文简体 Español

Español